Magnet ya juu ya coercivity NDFEB neodymium bar imeundwa kwa watenganisho wa sumaku. Imetengenezwa na sumaku za NDFEB (neodymium, chuma, boroni) zilizowekwa kwenye zilizopo za chuma. Baa hizi za sumaku zinafaa katika kuondoa uchafu wa chuma na chembe za chuma kutoka kwa malighafi.

Magneti yamekusanyika, svetsade na polished ili kuhakikisha utendaji wa hali ya juu. Zinafaa kwa programu ambazo zinahitaji sumaku zenye nguvu na za kudumu kuchuja uchafu wa chuma.

Baa za sumaku za NDFEB zinapatikana na nguvu za sumaku zinazoweza kubadilika kulingana na mahitaji ya wateja. Ikiwa ni sumaku za feri au sumaku za juu za NDFEB, tunaweza kutoa baa za sumaku ambazo zinakidhi mahitaji maalum ya nguvu ya uso.

Baa hizi za sumaku hutumiwa sana katika viwanda kama usindikaji wa chakula, dawa, na kuchakata tena. Ni bora kwa matumizi yanayojumuisha malighafi au inapita. Baa za sumaku za NDFEB zinafaa sana katika kutoa chembe za chuma na chuma, ambayo inaboresha usafi wa bidhaa ya mwisho.

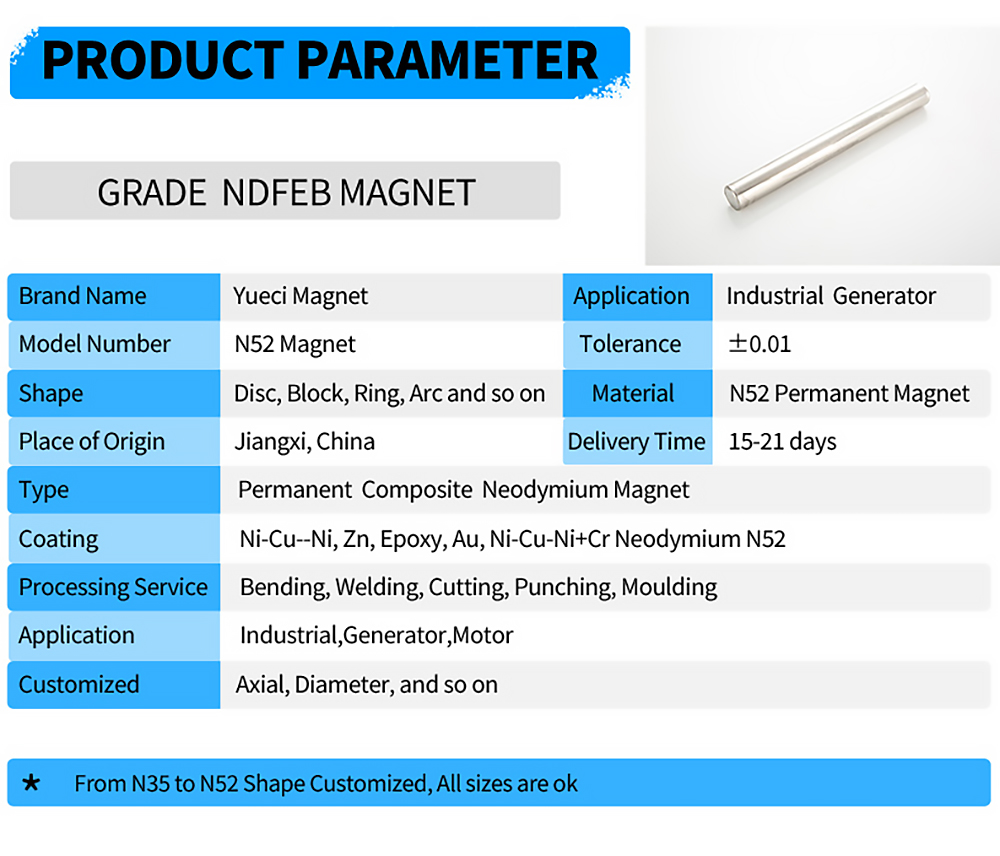

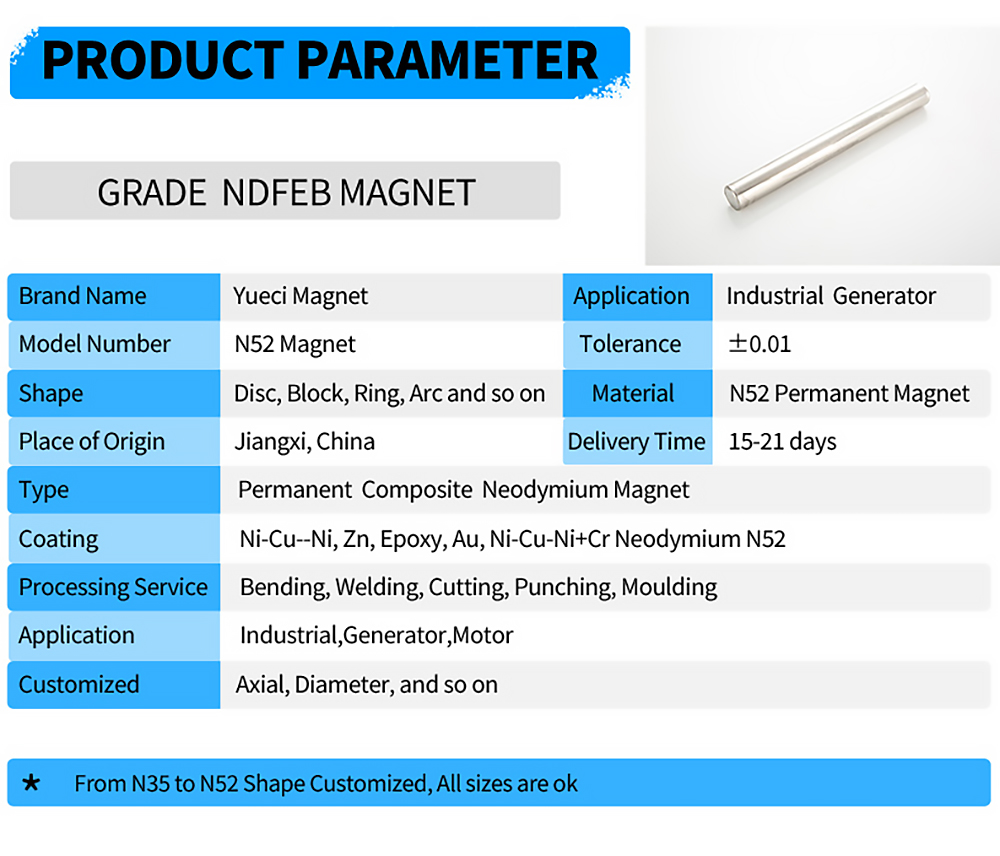

Viwango vya Bidhaa

| Parameta |

Viwango vya |

| Uvumilivu |

± 1% |

| Daraja |

NDFEB Magnet |

| Mahali pa asili |

Jiangxi, Uchina |

| Wakati wa kujifungua |

Siku 15-21 |

| Jina la chapa |

Yueci |

| Nambari ya mfano |

N52 sumaku |

| Aina |

Kudumu |

| Mchanganyiko |

Magnet ya Neodymium |

| Sura |

Disc, block, pete, arc, na zaidi |

| Maombi |

Sumaku ya viwandani |

| Huduma ya usindikaji |

Kuinama, kulehemu, kukata, kuchomwa, ukingo |

| Udhibitisho |

ISO9001: 2008, ISO/TS16949: 2009, ROHS |

| Nyenzo |

N52 sumaku ya kudumu |

| Daraja |

Imeboreshwa, kutoka N35 hadi N52 |

| Sura |

Imeboreshwa, saizi zote zinapatikana |

| Mipako |

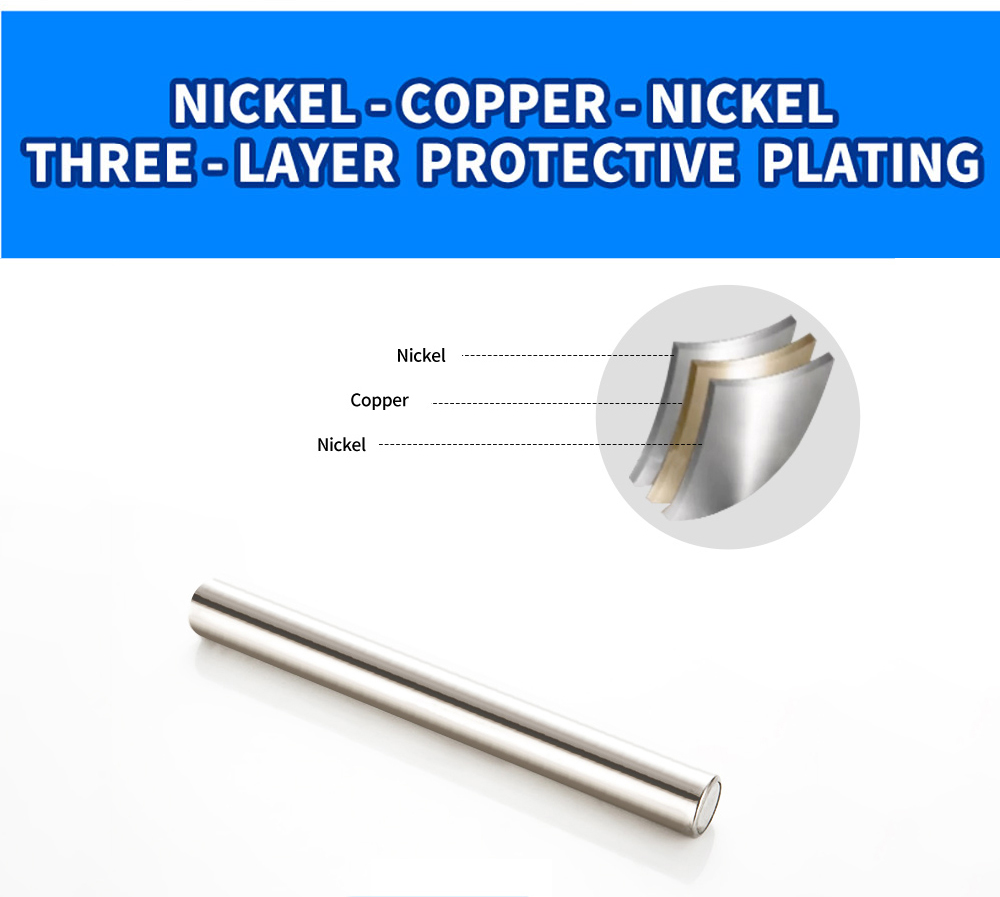

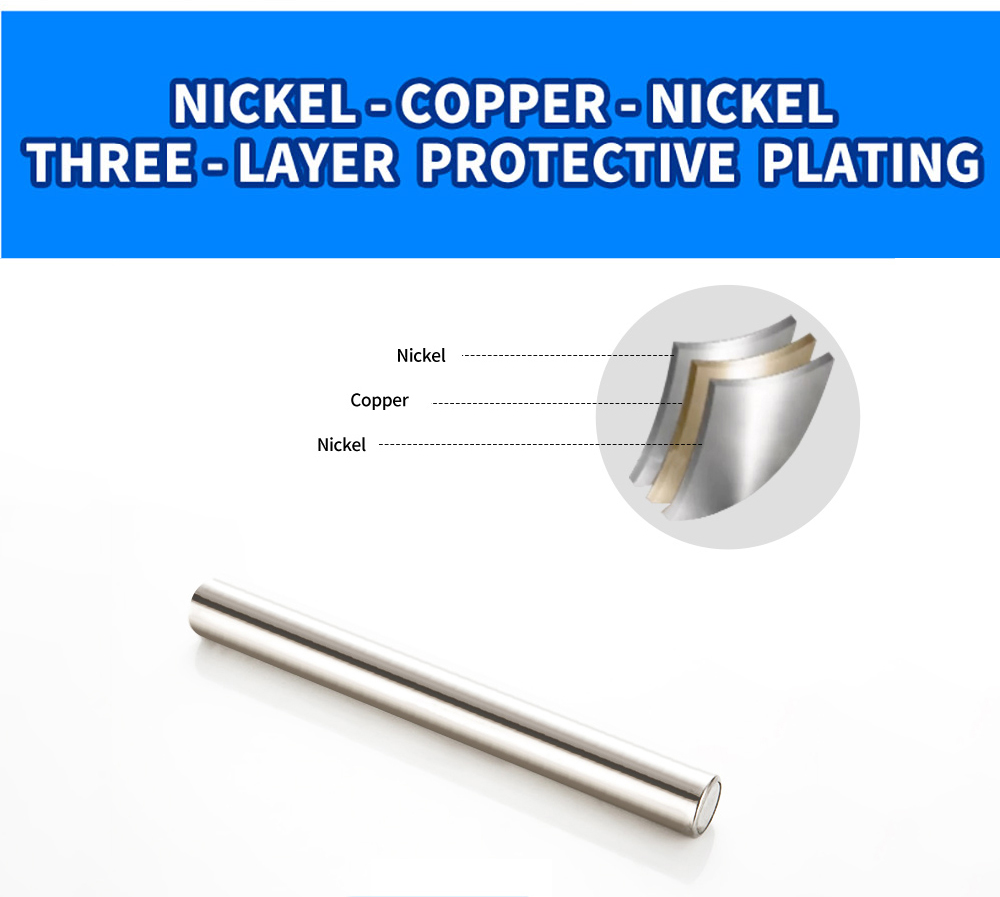

Ni-Cu-Ni, Zn, Epoxy, Au, Ni-Cu-Ni+Cr |

| Nguvu ya sumaku |

Umeboreshwa |

| Mwelekeo wa sumaku |

Imeboreshwa, axial, kipenyo, nk. |

Vipengee vya sumaku za juu za ndfeb bar neodymium

Rahisi kutenganisha na kusafisha:

Ubunifu unaruhusu disassembly rahisi na kusafisha, kuhakikisha matengenezo rahisi.

Hakuna matumizi ya nishati, uchafuzi wa sifuri:

Magneti hayatumii nishati na haitoi uchafuzi wakati wa kufanya kazi, kukuza maendeleo endelevu.

Ufanisi mkubwa na utulivu:

Nguvu ya nguvu ya nguvu na utendaji bora wakati wa matumizi ya muda mrefu.

Ubunifu rahisi na matumizi ya uzalishaji:

Inaweza kubinafsishwa kulingana na mahitaji maalum ya wateja na mahitaji ya matumizi.

Matumizi ya sumaku za juu za utendaji wa NDFEB:

Imetengenezwa kwa sumaku za NDFEB kwa nguvu ya juu na kuegemea.

Nguvu ya uso wa juu hadi 12000-14000 Gauss:

Baa ya sumaku inaweza kufikia nguvu ya juu ya uso, kuboresha ufanisi wake katika kuondoa uchafu wa chuma.

Manufaa ya sumaku ya juu ya ndfeb bar neodymium

Miundo ya kawaida ::

Iliyoundwa kwa mahitaji maalum ya wateja kwa anuwai ya matumizi ya viwandani.

Sumaku za premium:

Imetengenezwa na sumaku za NDFEB za daraja la N52 kwa nguvu ya nguvu ya nguvu na utendaji wa kuaminika.

Ujenzi wa kudumu:

Imetengenezwa na vifaa vya premium NDFEB, ni sugu kwa kutu na kuvaa, kuhakikisha uimara wa muda mrefu.

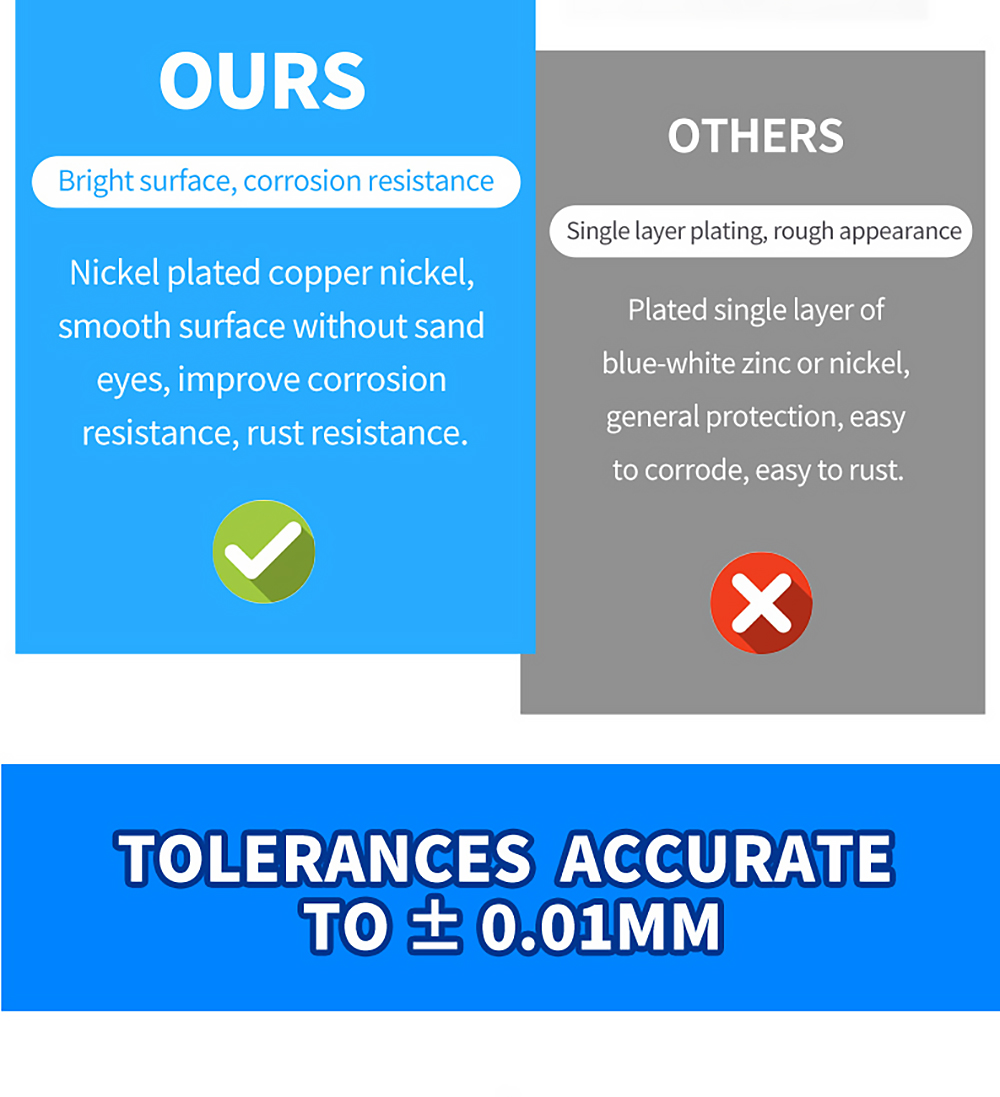

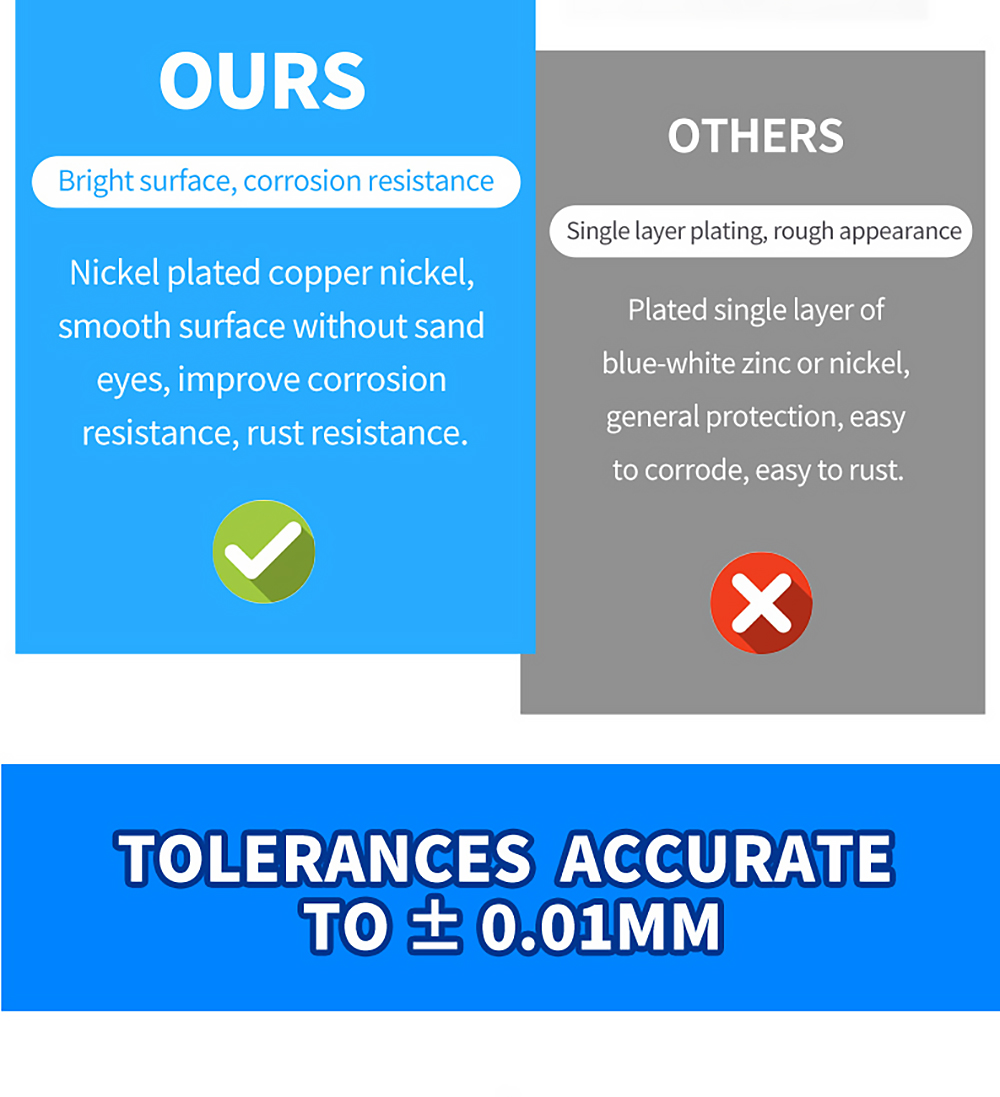

Uvumilivu sahihi:

Uvumilivu wa ± 0.05mm huhakikisha upatanishi sahihi na utendaji thabiti katika kudai mazingira ya viwandani.

ISO 9001: 2000 Ubora uliothibitishwa:

Kulingana na viwango vya kimataifa, kuhakikisha kuwa ya kuaminika, utendaji wa hali ya juu.

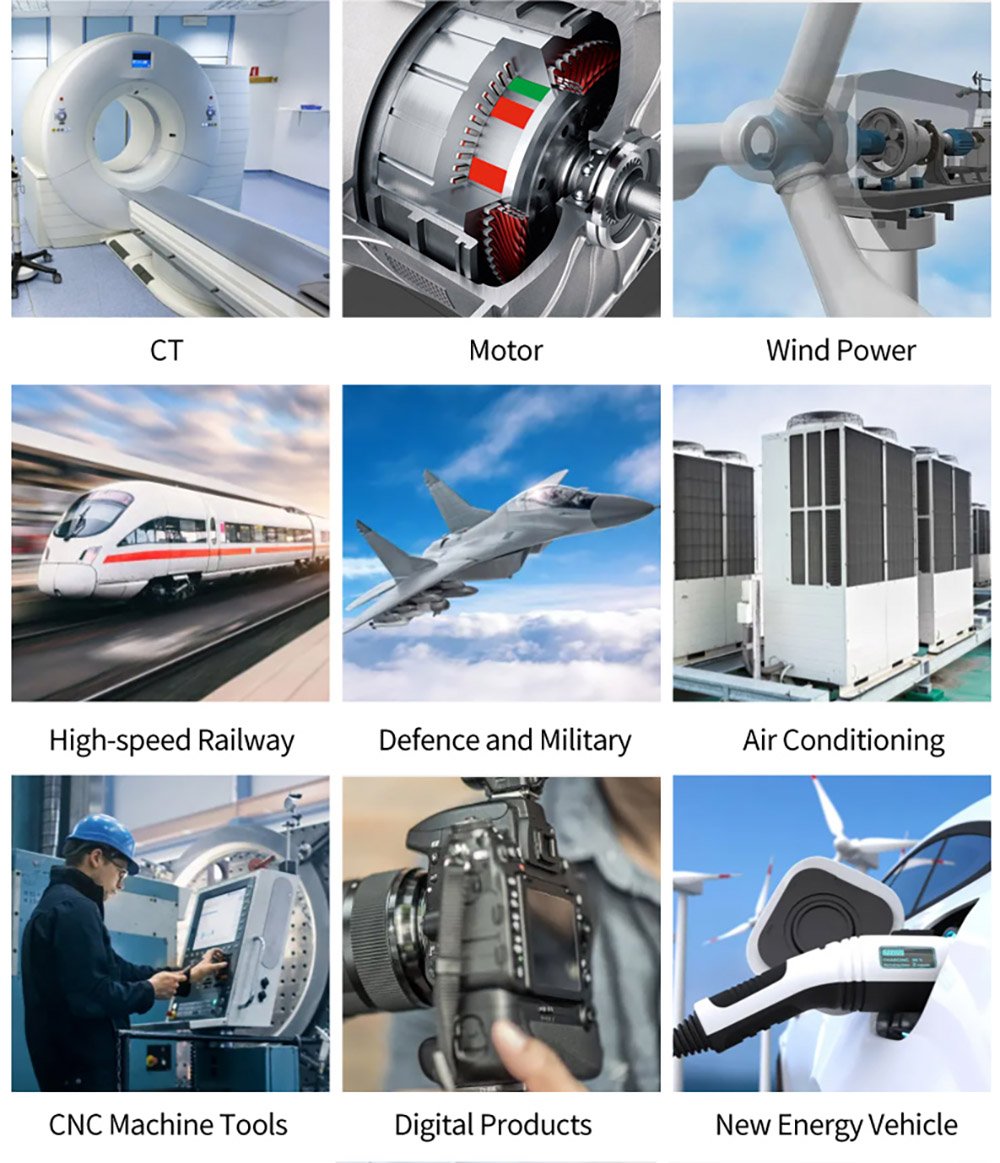

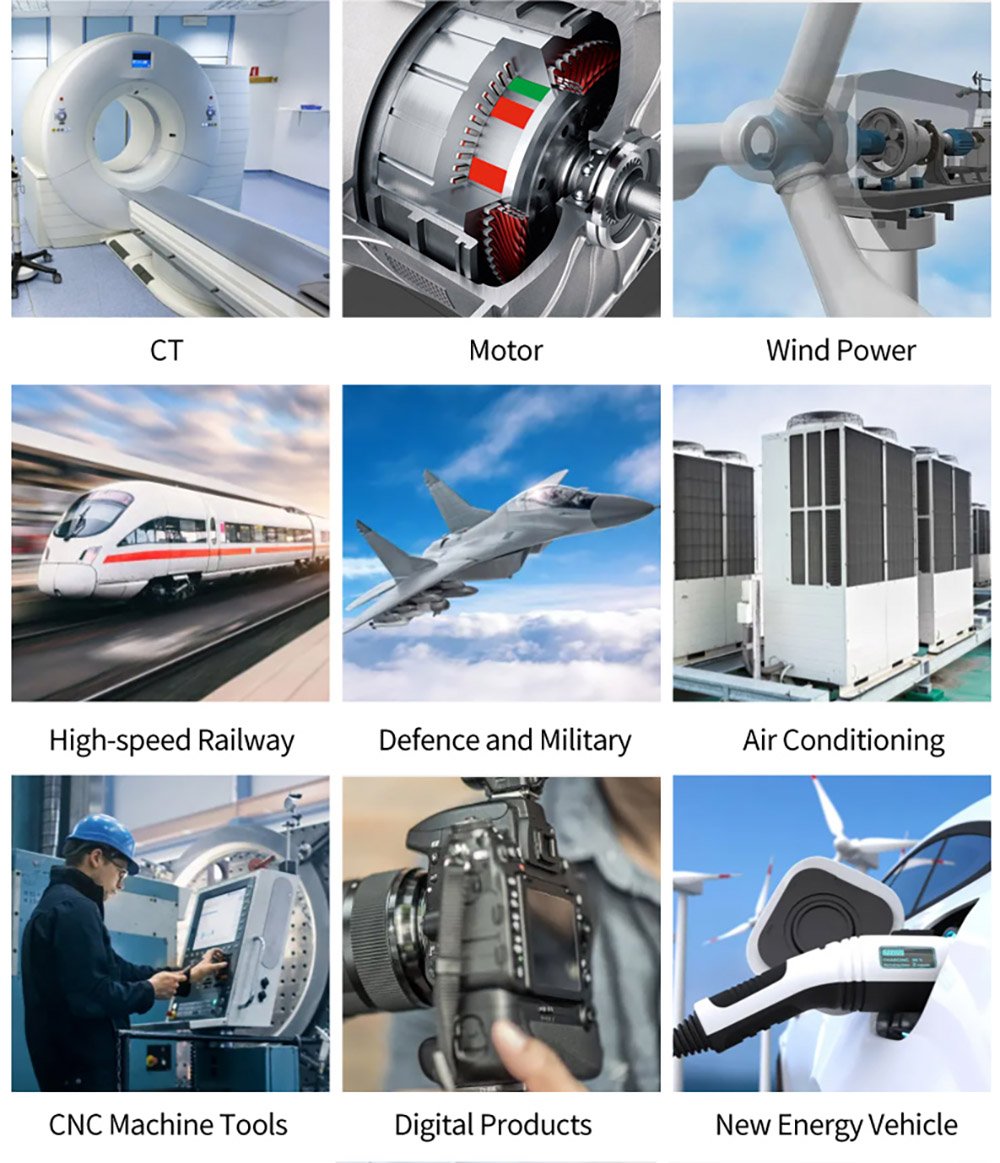

Maombi ya hali ya juu ya nguvu ya juu ya NDFEB BAR NEODYMIUM

Usindikaji wa Chakula:

Ondoa kwa ufanisi uchafu wa chuma kutoka kwa malighafi ili kuhakikisha usalama wa bidhaa na ubora.

Usindikaji wa bidhaa za kilimo na kando:

Inatumika kutenganisha uchafu wa chuma na bidhaa za kilimo na kuboresha usafi.

Sekta ya dawa:

Ni muhimu kwa kujitenga kwa sumaku na kuchuja ili kuondoa chembe za chuma ili kudumisha viwango vya juu vya bidhaa.

Mgawanyo wa sumaku na kuchuja:

Ni muhimu kuboresha ubora wa nyenzo kwa kuondoa uchafu wa chuma na chuma katika michakato mbali mbali ya viwandani.

Maswali ya juu ya coercivity ndfeb bar neodymium sumaku

1. Je! Ni nguvu gani ya sumaku ya sumaku ya fimbo ya Ndfeb?

Nguvu ya uso wa viboko hivi inaweza kufikia Gauss 12,000-14,000, kuhakikisha utengamano mzuri wa sumaku.

2. Jinsi ya kuhakikisha matengenezo sahihi ya sumaku za fimbo za NDFEB?

Sumaku hizi zimetengenezwa kutengwa kwa urahisi na kusafishwa, kuhakikisha matengenezo madogo wakati wa kutoa ufanisi mkubwa.

3. Je! Unaweza kutoa huduma za OEM/ODM kwa matumizi ya kawaida?

Ndio, tunatoa huduma kamili za OEM/ODM, pamoja na muundo, ubinafsishaji, na uzalishaji kwa mahitaji yako maalum.

4. Wakati wa kujifungua kwa viboko hivi vya sumaku ni muda gani?

Uwasilishaji kawaida huchukua siku 15-21, kulingana na kiasi cha agizo na mahitaji ya ubinafsishaji.

5. Je! Magneti ya kutu ni sugu?

Ndio, viboko vya NDFEB vimewekwa na vifaa vya kudumu kama vile Ni-Cu-Ni au Zn ili kuongeza upinzani wa kutu.

| Daraja |

Br |

HC |

HCB |

BH (max) |

| mt |

KGS |

koe |

ka/m |

koe |

ka/m |

MGOE |

KJ/M⊃3; |

| min |

max |

min |

max |

min |

min |

min |

min |

min |

max |

min |

max |

| N25 |

980 |

1020 |

9.8 |

10.2 |

8 |

637 |

|

|

22 |

27 |

175 |

215 |

| N28 |

1030 |

1070 |

10.3 |

10.7 |

8.5 |

677 |

|

|

25 |

30 |

199 |

239 |

| N30 |

1060 |

1100 |

10.6 |

11 |

9.5 |

756 |

|

|

27 |

32 |

215 |

255 |

| N33 |

1120 |

1140 |

11.2 |

11.4 |

10.5 |

836 |

|

|

30 |

35 |

239 |

279 |

| N34 |

1140 |

1170 |

11.4 |

11.7 |

11 |

876 |

|

|

31 |

36 |

247 |

287 |

| N35 |

1180 |

1220 |

11.8 |

12.2 |

12 |

955 |

10.9 |

868 |

33 |

37 |

263 |

295 |

| N38 |

1230 |

1250 |

12.3 |

12.5 |

12 |

955 |

11.3 |

899 |

36 |

40 |

287 |

318 |

| N40 |

1260 |

1280 |

12.6 |

12.8 |

12 |

955 |

11.6 |

923 |

38 |

42 |

302 |

334 |

| N42 |

1290 |

1320 |

12.9 |

13.2 |

12 |

955 |

11.6 |

923 |

40 |

44 |

318 |

350 |

| N45 |

1330 |

1380 |

13.3 |

13.8 |

12 |

955 |

11.0 |

876 |

43 |

47 |

342 |

374 |

| N48 |

1370 |

1420 |

13.7 |

14.2 |

12 |

955 |

11.2 |

892 |

45 |

50 |

358 |

398 |

| N50 |

1390 |

1440 |

13.9 |

14.4 |

12 |

955 |

11.0 |

876 |

47 |

52 |

374 |

414 |

| N52 |

1420 |

1470 |

14.2 |

14.7 |

12 |

955 |

11.0 |

876 |

49 |

54 |

390 |

4.30 |

| N54 |

1450 |

1490 |

14.5 |

14.9 |

11 |

876 |

9.0 |

716 |

51 |

56 |

406 |

446 |

| N55 |

1460 |

1520 |

14.6 |

15.2 |

11 |

876 |

9.0 |

716 |

52 |

57 |

414 |

454 |

| N56 |

1470 |

1530 |

14.7 |

15.3 |

11 |

876 |

9.0 |

716 |

53 |

58 |

422 |

462 |

| N58 |

1490 |

1550 |

14.9 |

15.5 |

11 |

876 |

9.0 |

716 |

55 |

60 |

438 |

478 |

| 35m |

1180 |

1220 |

11.8 |

12.2 |

14 |

1114 |

10.9 |

868 |

33 |

37 |

263 |

295 |

| 38m |

1230 |

1250 |

12.3 |

12.5 |

14 |

1114 |

11.3 |

899 |

36 |

40 |

287 |

318 |

| 40M |

1260 |

1280 |

12.6 |

12.8 |

14 |

1114 |

11.6 |

923 |

38 |

42 |

302 |

334 |

| 42m |

1290 |

1320 |

12.9 |

13.2 |

14 |

1114 |

12.0 |

955 |

40 |

44 |

318 |

350 |

| 45m |

1330 |

1380 |

13.3 |

13.8 |

14 |

1114 |

12.5 |

995 |

43 |

47 |

342 |

374 |

| 48m |

1370 |

1420 |

13.7 |

14.2 |

14 |

1114 |

12.8 |

1019 |

45 |

50 |

358 |

398 |

| 50m |

1390 |

1440 |

13.9 |

14.4 |

14 |

1114 |

13.0 |

1035 |

47 |

52 |

374 |

414 |

| 52m |

1420 |

1470 |

14.2 |

14.7 |

13 |

1035 |

12.5 |

995 |

49 |

54 |

390 |

430 |

| 55m |

1460 |

1520 |

14.6 |

15.2 |

13 |

1035 |

12.8 |

1019 |

52 |

57 |

414 |

454 |

| 30h |

1080 |

1140 |

10.8 |

11.4 |

17 |

1353 |

10.3 |

820 |

27 |

32 |

215 |

255 |

| 33h |

1140 |

1180 |

11.4 |

11.8 |

17 |

1353 |

10.6 |

844 |

31 |

35 |

247 |

279 |

| 35h |

1180 |

1220 |

11.8 |

12.2 |

17 |

1353 |

10.9 |

868 |

33 |

37 |

263 |

295 |

| 38h |

1230 |

1250 |

12.3 |

12.5 |

17 |

1353 |

11.3 |

899 |

36 |

40 |

287 |

318 |

| Daraja |

Br |

HCI |

HCB |

BH (max ) |

| mt |

KGS |

koe |

ka/m |

koe |

ka/m |

MGOE |

KJ/M^3 |

| min |

max |

min |

max |

min |

min |

min |

min |

min |

max |

min |

max |

| 40h |

1260 |

1280 |

12.6 |

12.8 |

17 |

1353 |

11.6 |

923 |

38 |

42 |

302 |

334 |

| 42h |

1290 |

1320 |

12.9 |

13.2 |

17 |

1353 |

12.0 |

955 |

40 |

44 |

318 |

350 |

| 45h |

1330 |

1380 |

13.3 |

13.8 |

17 |

1353 |

12.2 |

971 |

43 |

47 |

342 |

374 |

| 48h |

1370 |

1420 |

13.7 |

14.2 |

17 |

1353 |

12.9 |

1027 |

45 |

50 |

358 |

398 |

| 50h |

1390 |

1440 |

13.9 |

14.4 |

17 |

1353 |

13.0 |

1035 |

47 |

52 |

374 |

414 |

| 52h |

1420 |

1470 |

14.2 |

14.7 |

17 |

1353 |

13.2 |

1051 |

49 |

54 |

390 |

430 |

| 54h |

1440 |

1500 |

14.4 |

15 |

16 |

1274 |

13.5 |

1075 |

51 |

56 |

406 |

446 |

| 55h |

1460 |

1520 |

14.6 |

15.2 |

16 |

1274 |

13.5 |

1075 |

52 |

57 |

414 |

454 |

| 30sh |

1080 |

1140 |

10.8 |

11.4 |

20 |

1592 |

10.3 |

820 |

27 |

32 |

215 |

255 |

| 33sh |

1140 |

1170 |

11.4 |

11.7 |

20 |

1592 |

10.6 |

844 |

31 |

35 |

247 |

279 |

| 35sh |

1180 |

1220 |

11.8 |

12.2 |

20 |

1592 |

11.0 |

876 |

33 |

37 |

263 |

295 |

| 38sh |

1230 |

1250 |

12.3 |

12.5 |

20 |

1592 |

11.4 |

907 |

36 |

40 |

287 |

318 |

| 40sh |

1260 |

1280 |

12.6 |

12.8 |

20 |

1592 |

11.8 |

939 |

38 |

42 |

302 |

334 |

| 42SH |

1290 |

1320 |

12.9 |

13.2 |

20 |

1592 |

12.2 |

971 |

40 |

44 |

318 |

350 |

| 45sh |

1330 |

1380 |

13.3 |

13.8 |

20 |

1592 |

12.3 |

979 |

43 |

47 |

342 |

374 |

| 48sh |

1370 |

1420 |

13.7 |

14.2 |

20 |

1592 |

12.5 |

995 |

45 |

50 |

358 |

398 |

| 50sh |

1390 |

1440 |

13.9 |

14.4 |

19 |

1512 |

13.0 |

1035 |

47 |

52 |

374 |

414 |

| 52sh |

1420 |

1470 |

14.2 |

14.7 |

19 |

1512 |

13.2 |

1051 |

49 |

54 |

390 |

430 |

| 54SH |

1450 |

1500 |

14.5 |

15 |

19 |

1512 |

13.5 |

1075 |

51 |

56 |

406 |

446 |

| 30UH |

1080 |

1130 |

10.8 |

11.3 |

25 |

1990 |

10.2 |

812 |

28 |

32 |

223 |

255 |

| 33UH |

1140 |

1170 |

11.4 |

11.7 |

25 |

1990 |

10.7 |

852 |

31 |

35 |

247 |

279 |

| 35UH |

1180 |

1220 |

11.8 |

12.2 |

25 |

1990 |

10.8 |

860 |

33 |

37 |

263 |

295 |

| 38UH |

1230 |

1250 |

12.3 |

12.5 |

25 |

1990 |

11.0 |

876 |

36 |

40 |

287 |

318 |

| 40UH |

1260 |

1280 |

12.6 |

12.8 |

25 |

1990 |

11.5 |

915 |

38 |

42 |

302 |

334 |

| 42UH |

1290 |

1330 |

12.9 |

13.3 |

25 |

1990 |

12.2 |

971 |

40 |

44 |

318 |

350 |

| 45UH |

1330 |

1380 |

13.3 |

13.8 |

25 |

1990 |

12.6 |

1003 |

43 |

47 |

342 |

374 |

| 48uh |

1370 |

1420 |

13.7 |

14.2 |

24 |

1910 |

12.5 |

995 |

45 |

50 |

358 |

398 |

| 50UH |

1390 |

1440 |

13.9 |

14.4 |

24 |

1910 |

13.0 |

1035 |

47 |

52 |

374 |

414 |

| 52UH |

1420 |

1470 |

14.2 |

14.7 |

24 |

1910 |

13.2 |

1051 |

49 |

54 |

390 |

430 |

| 30eh |

1080 |

1130 |

10.8 |

11.3 |

30 |

2388 |

10.2 |

812 |

28 |

32 |

223 |

255 |

| 33eh |

1140 |

1170 |

11.4 |

11.7 |

30 |

2388 |

10.3 |

820 |

31 |

35 |

247 |

279 |

| 35eh |

1180 |

1220 |

11.8 |

12.2 |

30 |

2388 |

10.5 |

836 |

33 |

37 |

263 |

295 |

| 38eh |

1220 |

1250 |

12.2 |

12.5 |

30 |

2388 |

11.5 |

915 |

35 |

40 |

279 |

318 |

| 40eh |

1250 |

1280 |

12.5 |

12.8 |

30 |

2388 |

11.9 |

947 |

37 |

42 |

295 |

334 |

| 42eh |

1280 |

1320 |

12.8 |

13.2 |

29 |

2308 |

12.2 |

971 |

39 |

44 |

310 |

350 |

| 45eh |

1320 |

1380 |

13.2 |

13.8 |

29 |

2308 |

12.6 |

1003 |

42 |

47 |

334 |

374 |

| 48eh |

1370 |

1420 |

13.7 |

14.2 |

29 |

2308 |

12.5 |

995 |

45 |

50 |

358 |

398 |

| 50eh |

1390 |

1440 |

13.9 |

14.4 |

29 |

2308 |

13.0 |

1035 |

47 |

52 |

374 |

414 |

| Daraja |

Br |

HCJ |

HCB |

BH ( Max ) |

| mt |

KGS |

koe |

ka/m |

koe |

ka/m |

MGOE |

KJ/M^3 |

| mim |

max |

mm |

Tr |

min |

min |

min |

mim |

MML |

m2x |

min |

max |

| 28ah |

1020 |

1090 |

10.2 |

10.9 |

34 |

2760 |

9.8 |

780 |

25 |

30 |

199 |

239 |

| 30ah |

1070 |

1130 |

10.7 |

11.3 |

34 |

2760 |

10.2 |

812 |

27 |

32 |

215 |

255 |

| 33ah |

1110 |

1170 |

11.1 |

11.7 |

34 |

2706 |

10.5 |

836 |

30 |

35 |

239 |

279 |

| 35ah |

1170 |

1220 |

11.7 |

12.2 |

34 |

2706 |

10.5 |

836 |

32 |

37 |

255 |

295 |

| 38ah |

1220 |

1250 |

12.2 |

12.5 |

34 |

2706 |

11.5 |

915 |

35 |

40 |

279 |

318 |

| 40ah |

1250 |

1280 |

12.5 |

12.8 |

34 |

2706 |

11.9 |

947 |

37 |

42 |

295 |

334 |

| 42ah |

1280 |

1320 |

12.8 |

13.2 |

34 |

2706 |

12.2 |

971 |

39 |

44 |

310 |

350 |