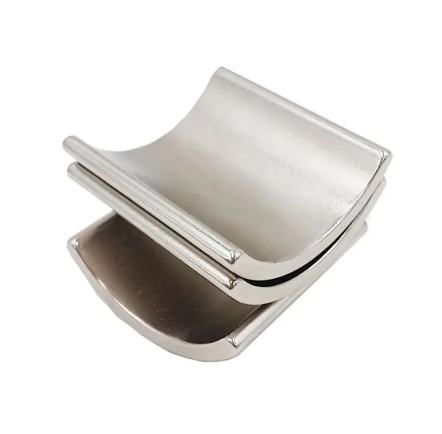

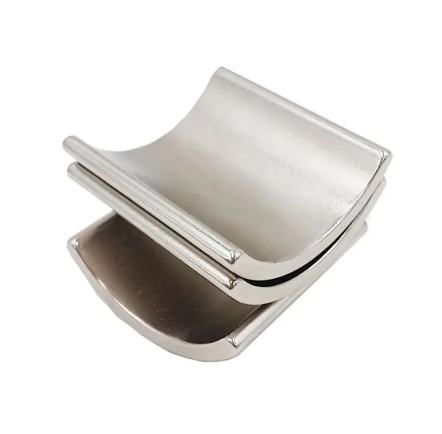

Yueci offers high performance NdFeB N52 magnets for motors . These magnets are made of high quality neodymium material.

Each magnet has a tolerance of ±1%. This ensures accuracy in a variety of applications. The N52 grade provides strong magnetic force for effective operation.

Magnets are available in various shapes including discs, blocks, rings, and arcs. Custom shapes and sizes are available to meet your needs.

Yueci has been in operation since 2012. Our products are certified to ISO9001 and ROHS standards to ensure quality.

Our magnet delivery time is usually 15 to 21 days. We provide processing services such as bending, welding, cutting, etc.

Our magnets can be coated with nickel-copper-nickel, zinc, or epoxy. These coatings prevent corrosion and wear.

Product Parameters

| Parameter | Value |

| Tolerance | ±1% |

| Grade | NdFeB Magnet |

| Place of Origin | Jiangxi, China |

| Delivery Time | 15-21 days |

| Brand Name | N52 NdFeB Magnet |

| Model Number | N52 Magnet |

| Type | Permanent |

| Composite | Neodymium Magnet |

| Shape | Disc, Block, Ring, Arc, etc. |

| Application | Industrial Magnet |

| Processing Service | Bending, Welding, Cutting, etc. |

| Certifications | ISO9001:2008, ISO/TS16949:2009, ROHS |

| Founded | Since 2012 |

| Material | N52 Permanent Magnet |

| Grade | Customized, From N35 to N52 |

| Coating | Ni-Cu-Ni, Zn, Epoxy, Au, etc. |

| Magnetic Force | Customized |

| Magnetization Direction | Customized, Axial, Diameter, etc. |

Features of High Performance NdFeB N52 Magnets

Type: These magnets are permanent magnets designed for durability and reliability.

Composite Material: Made from rare earth neodymium, they offer excellent magnetic strength.

Shape Options: Available in curved shapes, with custom options such as blocks, discs, and rings.

Coating Options: Available in a variety of coatings including nickel, zinc, and epoxy for protection.

Applications: Ideal for use as industrial magnets in a variety of manufacturing processes.

Certifications: Meets standards such as ISO 9001, IATF 16949, and RoHS.

Manufacturing Method: Produced using a sintering process for superior performance.

Packaging: Shipped using ocean pallets, air freight cartons, or express packaging options.

Advantages of of High Performance NdFeB N52 Magnets

Super Strong Neodymium Magnets: Designed for motors and suitable for a wide range of industrial applications.

Custom Size Factory: Products can be customized to customer specifications for easy integration into different systems.

Custom Color Options: Color customization is available to help the product blend in with the environment.

Custom Shape Options: Shapes are customizable, including discs, blocks, rings, and arcs, with flexibility for other designs.

Strong Coatings: All shapes come with high-quality coatings for enhanced durability and corrosion resistance.

High Energy Product: Sintered NdFeB magnets offer the highest energy product of all available materials, ensuring superior performance.

Various Shapes and Grades: A wide range of shapes, sizes, and grades are available to meet specific needs.

Application Scenarios of High Performance NdFeB N52 Magnets

Hardware Machinery: Used in various mechanical parts to enhance functionality.

Magnetic Tool Holder: Great for creating magnetic tool holders in workshops and garages.

Toys: Used in toys with magnetic functionality and playability.

Packaging Solutions: Used in packaging systems to effectively protect items.

Microphone: Integrated into microphones to improve sound quality and performance.

FAQs of High Performance NdFeB N52 Magnets

1.Are there any specific handling instructions for these magnets?

Yes, proper handling is recommended to avoid damage and maintain performance.

2. How does the coating on these magnets affect their performance?

The coating prevents corrosion and extends the life of the magnets.

3. What is the typical service life of NdFeB N52 magnets?

With proper care, these magnets can last for many years without significant loss of strength.

4. Can these magnets be used in high temperature applications?

Yes, but it is important to verify the specific temperature rating for your application.

5. What is the magnetization direction of these magnets?

The magnetization direction can be customized to your requirements.