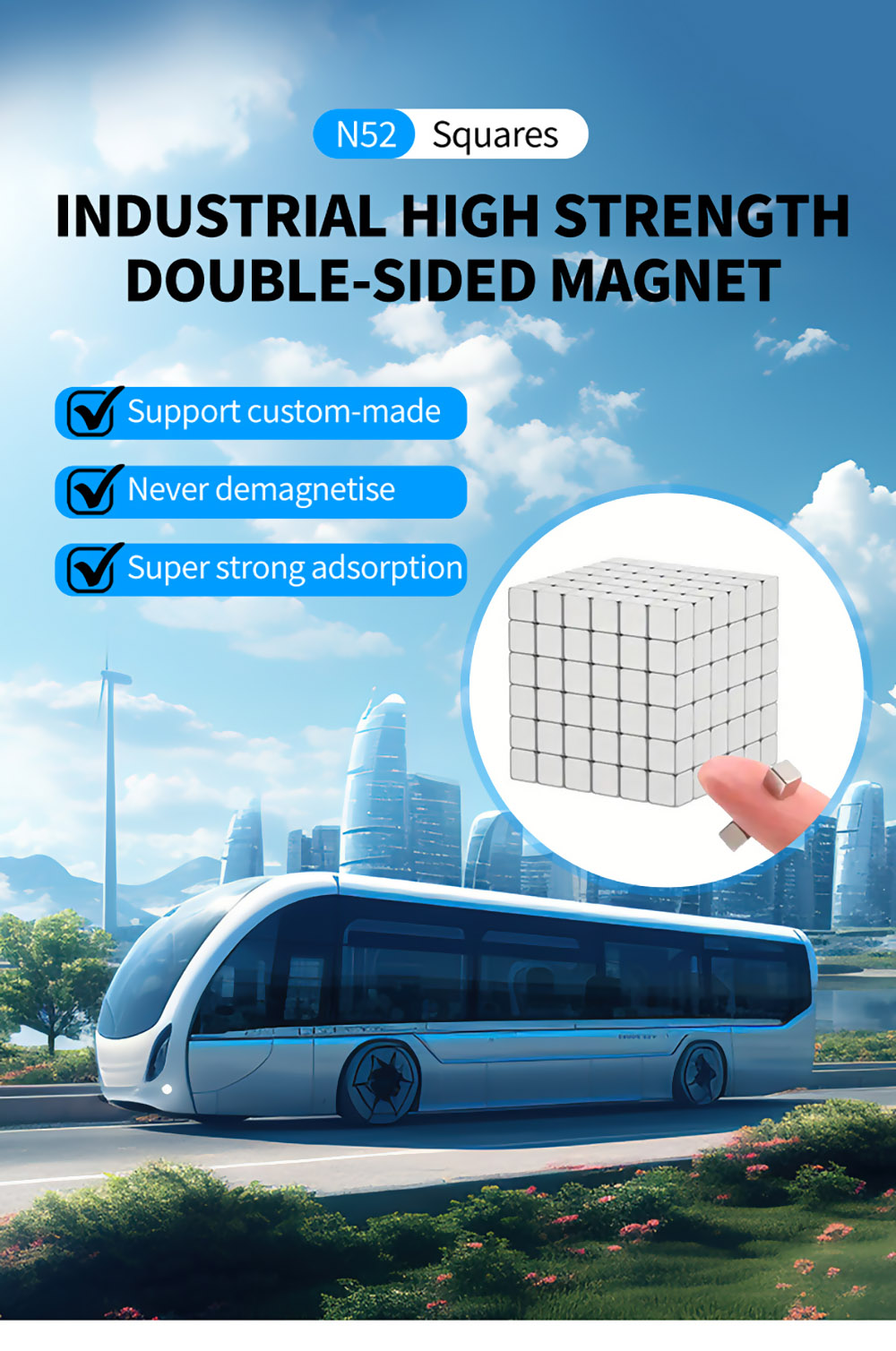

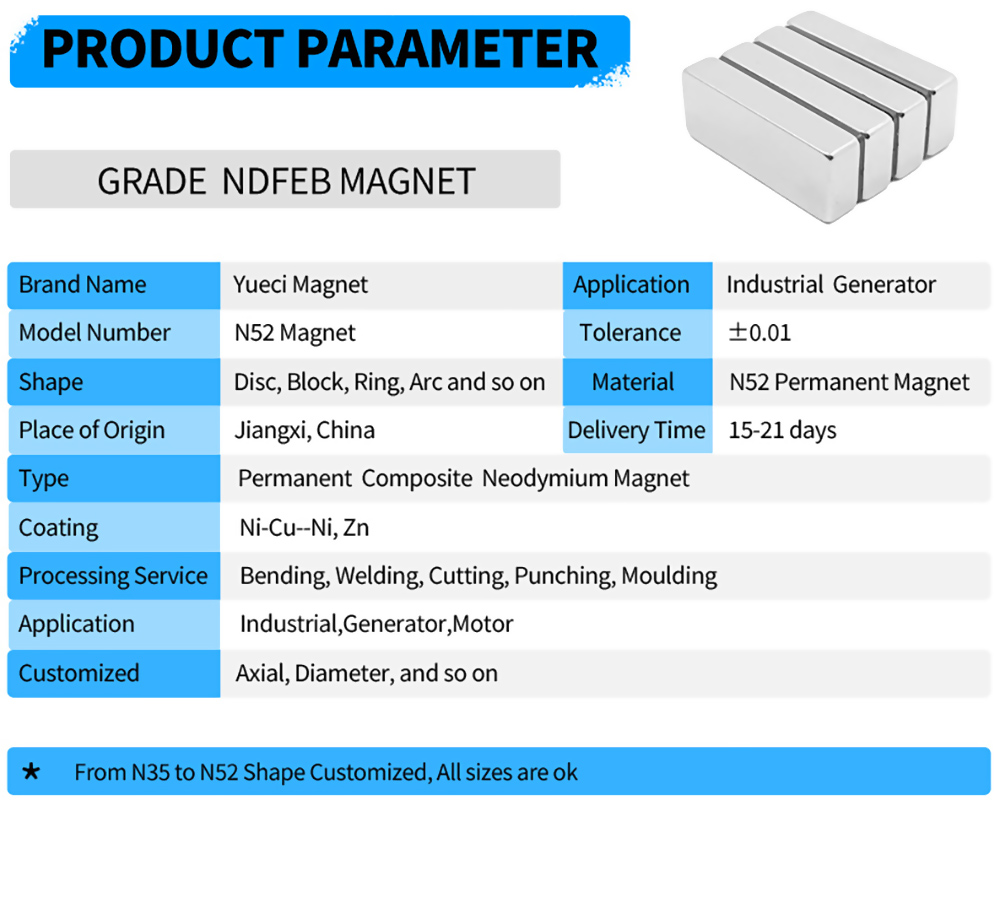

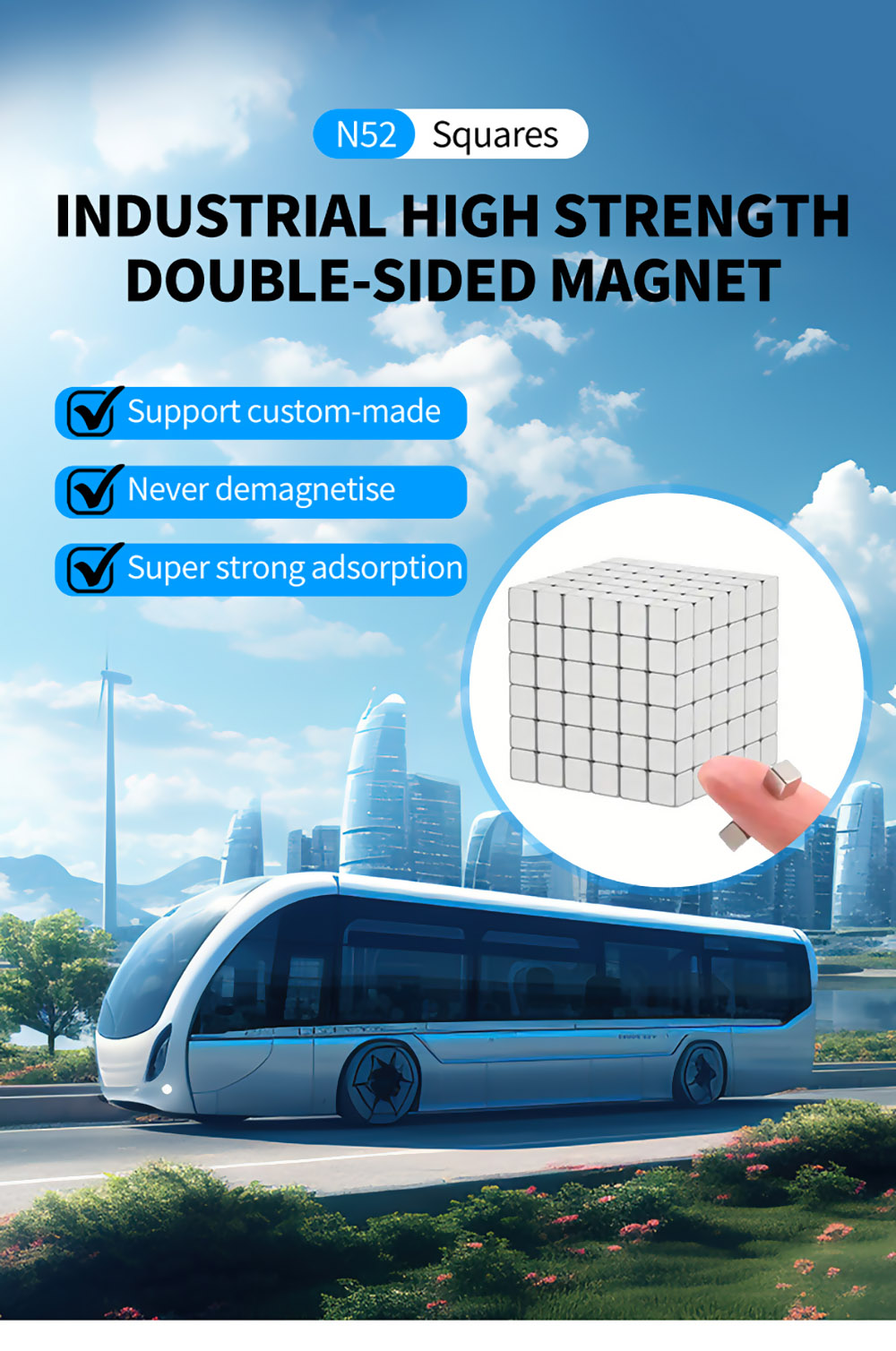

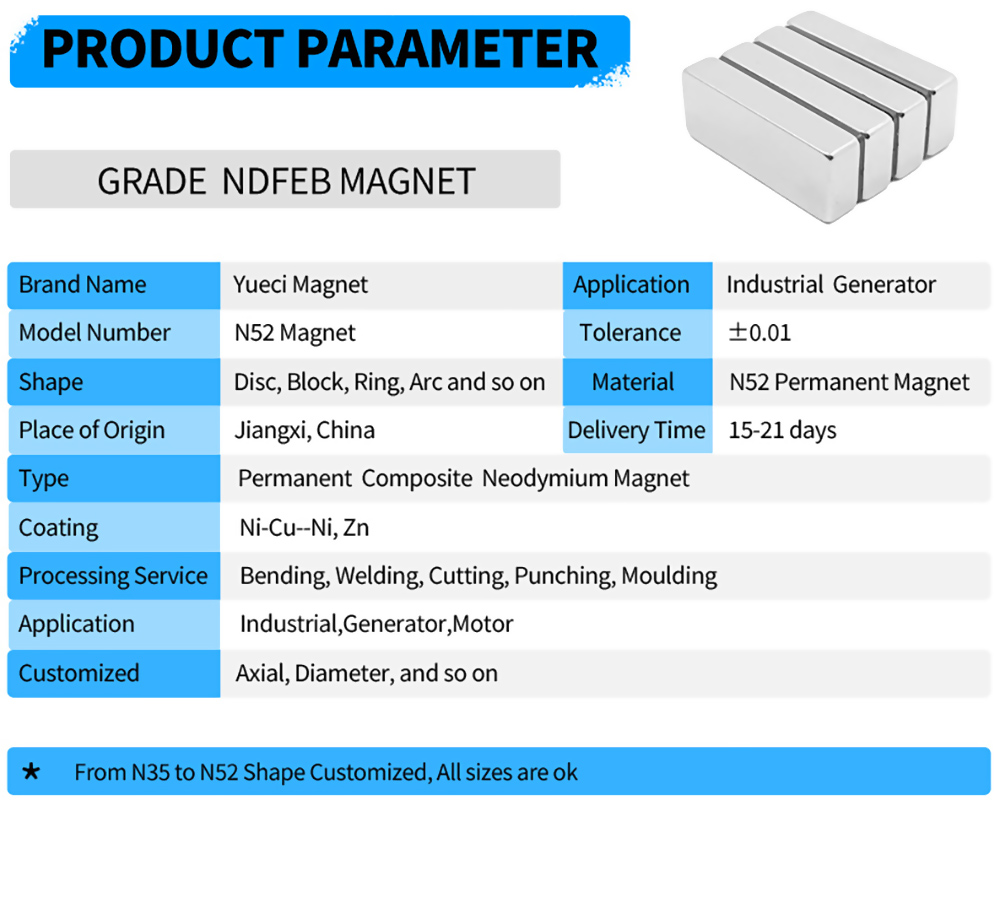

The Adjustable NdFeB Magnet Magnetic Square is ideal for engineering and manufacturing tasks. It is made with high-grade N52 neodymium magnets for excellent strength and precision.

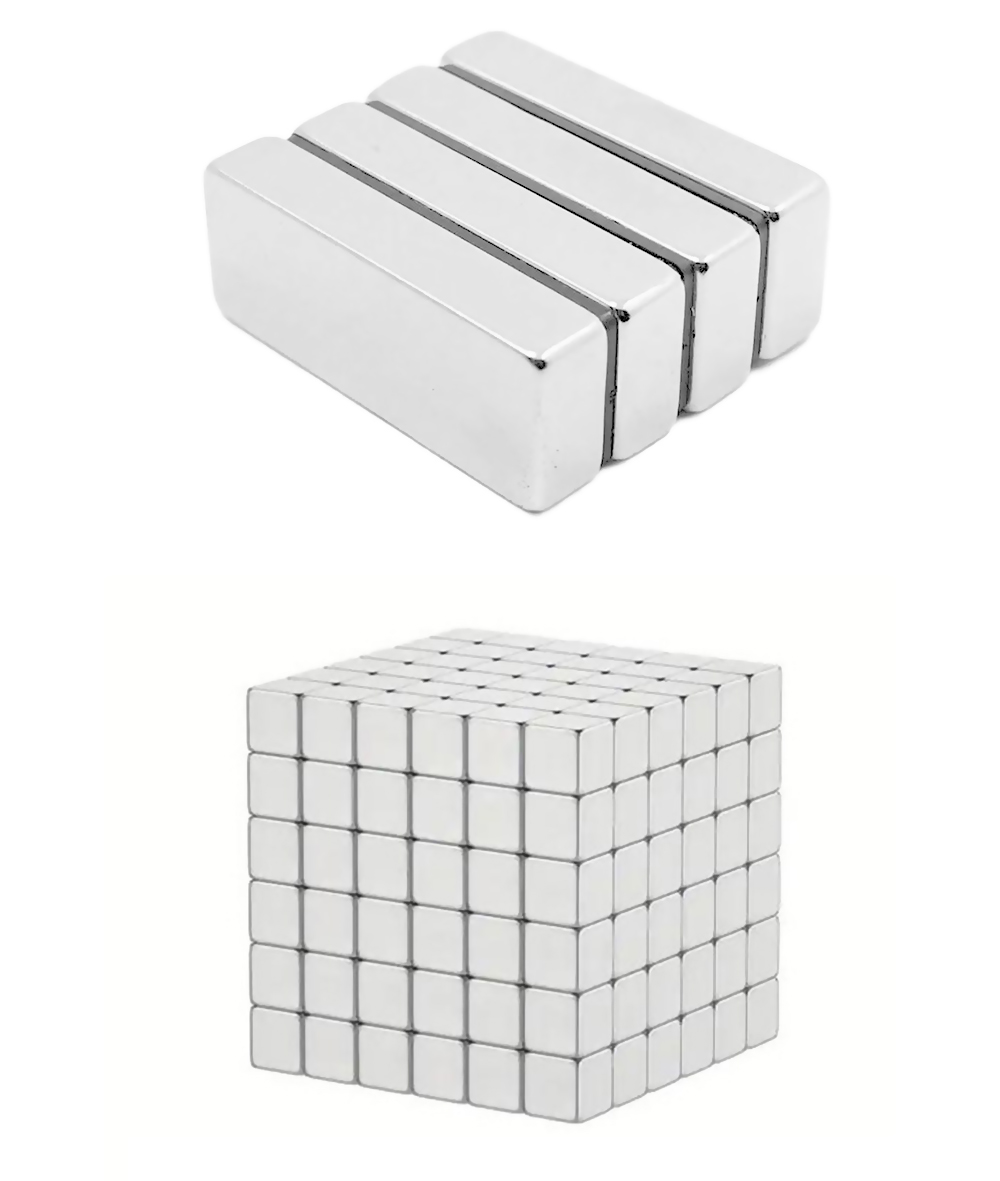

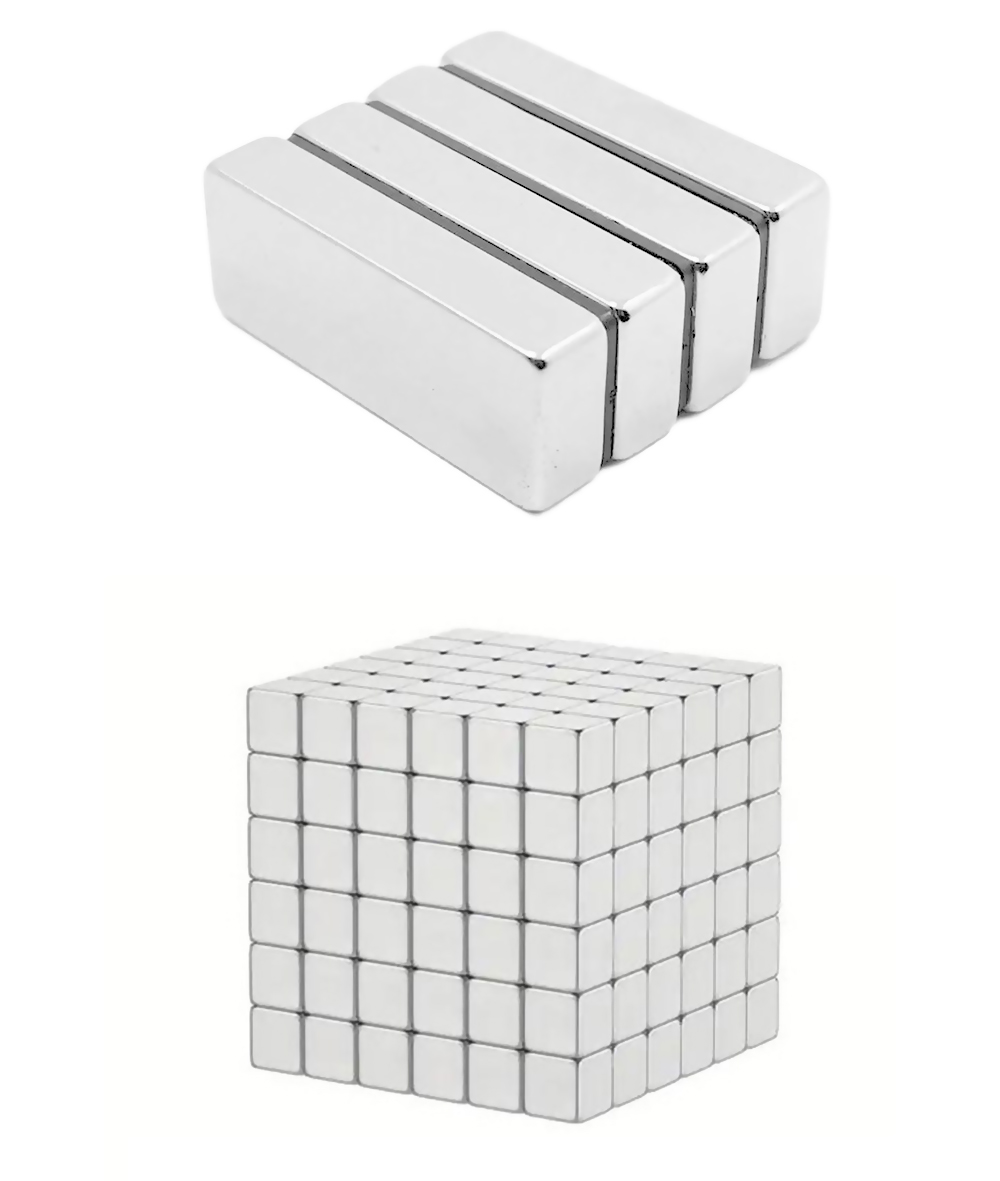

The product can be customized to meet the unique requirements of a variety of industrial applications. It is available in shapes such as discs, blocks, rings and arcs to meet a variety of needs.

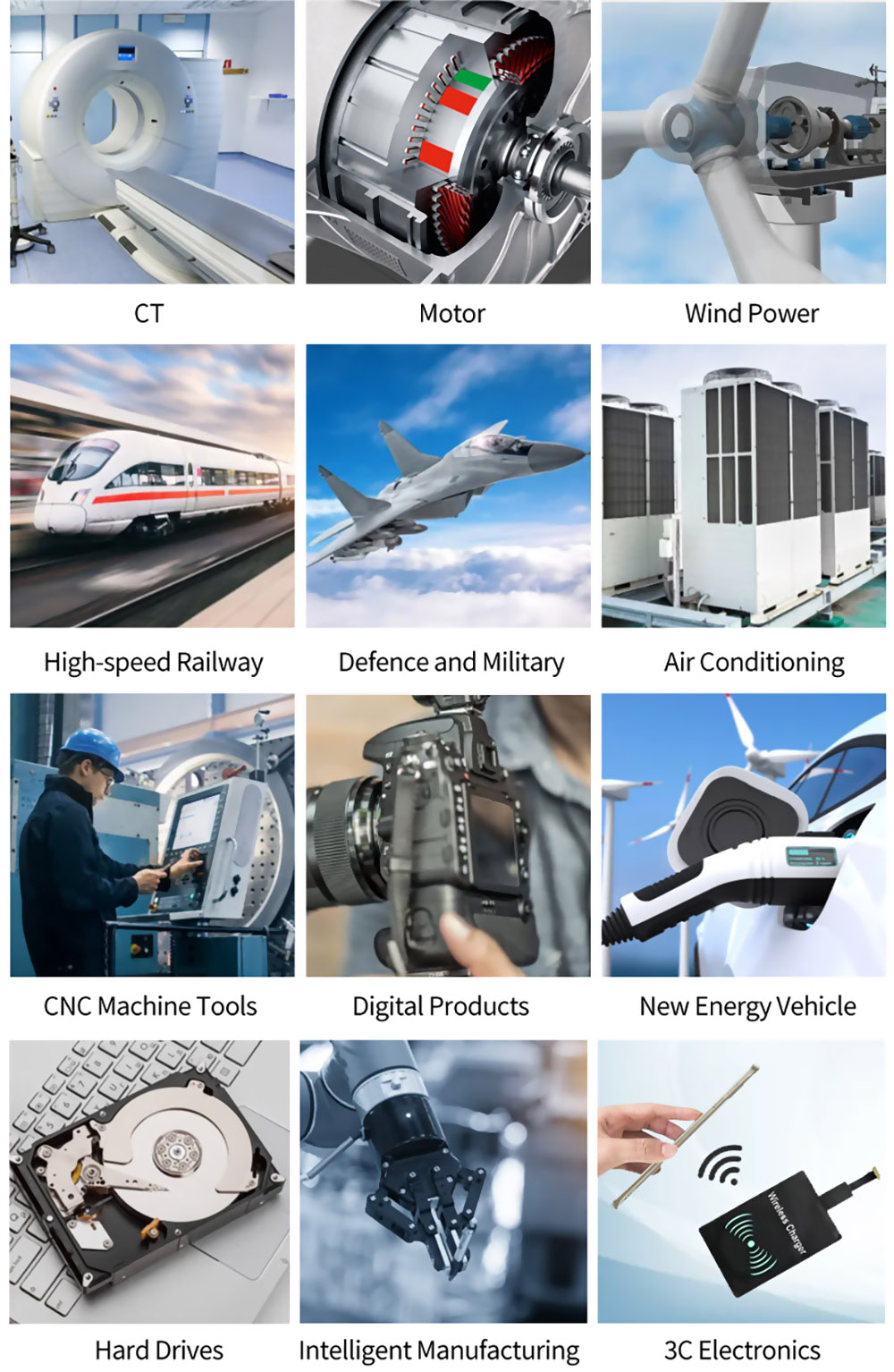

The Adjustable NdFeB Magnet Magnetic Square is manufactured in Jiangxi, China with a precision tolerance of ±1%. It is ideal for industrial uses including generators, motors and other machinery.

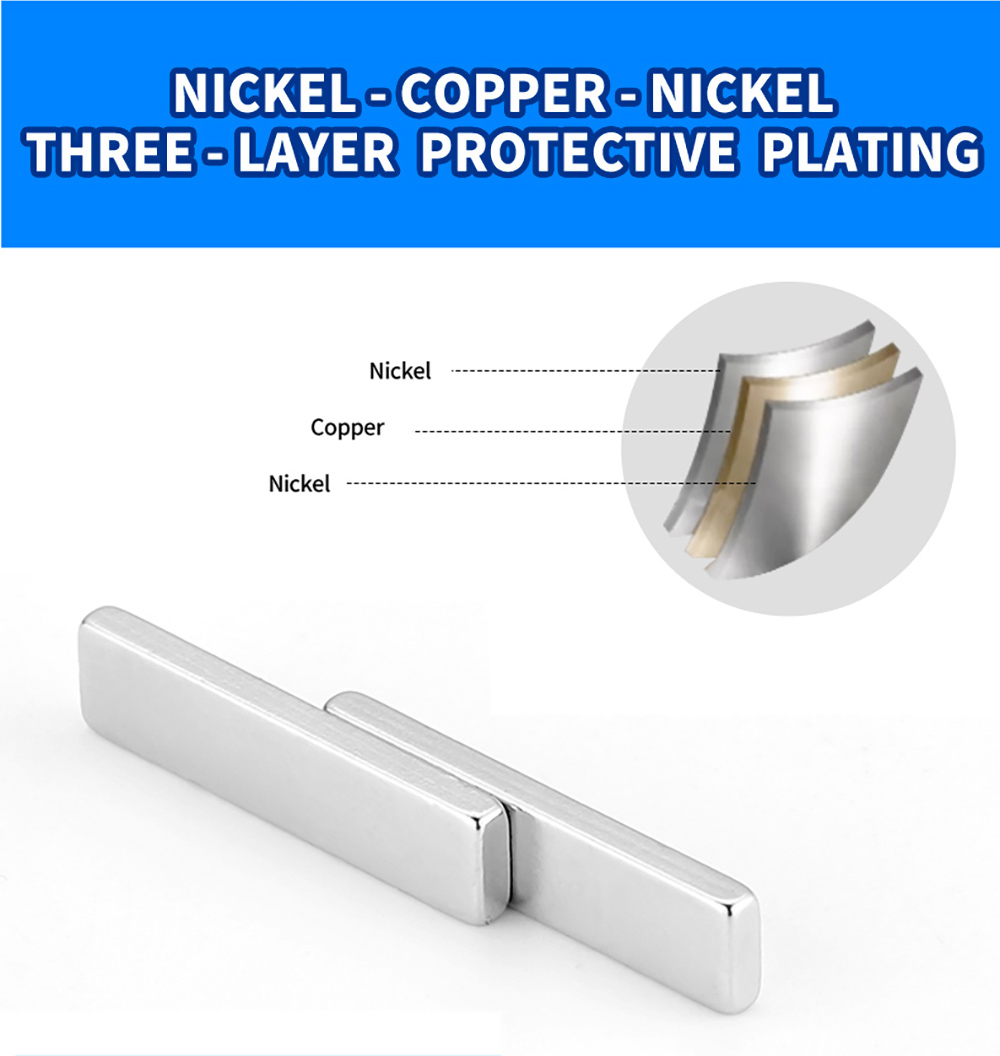

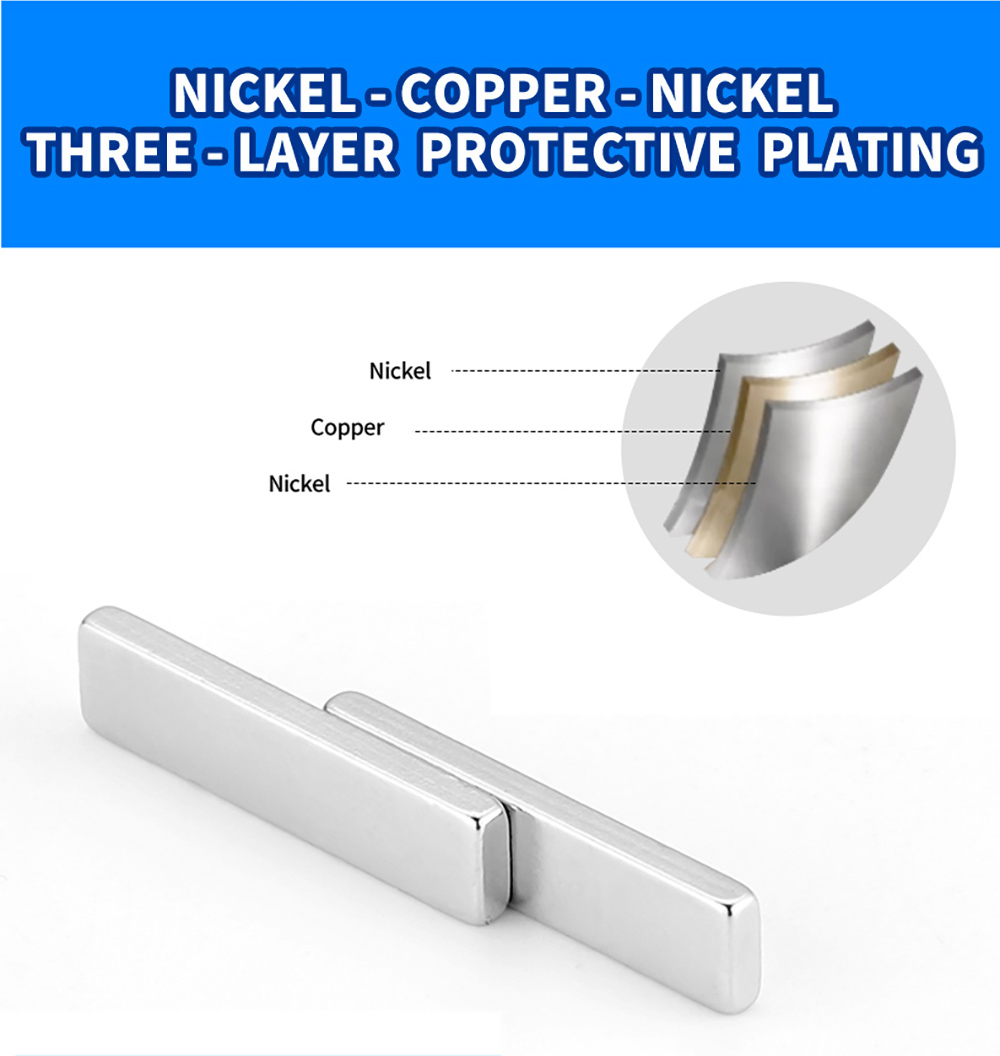

The NdFeB Magnet magnetic square is coated with durable Ni-Cu-Ni or Zn, ensuring excellent corrosion resistance and long-lasting performance. It can be processed by bending, welding, cutting, stamping and forming.

The Adjustable NdFeB Magnet Magnetic Square is certified by ISO9001:2008, ISO/TS16949:2009 and RoHS, meeting international quality standards. Delivery time is typically 15-21 days, ensuring reliable and fast service.

Product Attributes Table

| Parameter | Value |

| Tolerance | ±1% |

| Grade | N52 Neodymium Magnet |

| Place of Origin | Jiangxi, China |

| Brand Name | Yueci |

| Model Number | Customizable |

| Type | Permanent Magnet |

| Composite | Neodymium Magnet |

| Shape | Disc, Block, Ring, Arc, Customized |

| Application | Industrial, Generator, Motor |

| Processing Service | Bending, Welding, Cutting, Punching, Moulding |

| Material | N52 Permanent Magnet |

| Coating | Ni-Cu-Ni, Zn |

| Magnetic Force | Customized |

| Magnetization Direction | Axial, Diameter, Customized |

| Certification | ISO9001:2008, ISO/TS16949:2009, RoHS |

Features of Adjustable NdFeB Magnet Magnetic Square

Customizable Shapes and Sizes: Available in a variety of shapes and sizes to meet specific industrial needs.

High Strength N52 Neodymium Magnets: Provides excellent magnetic force for reliable performance.

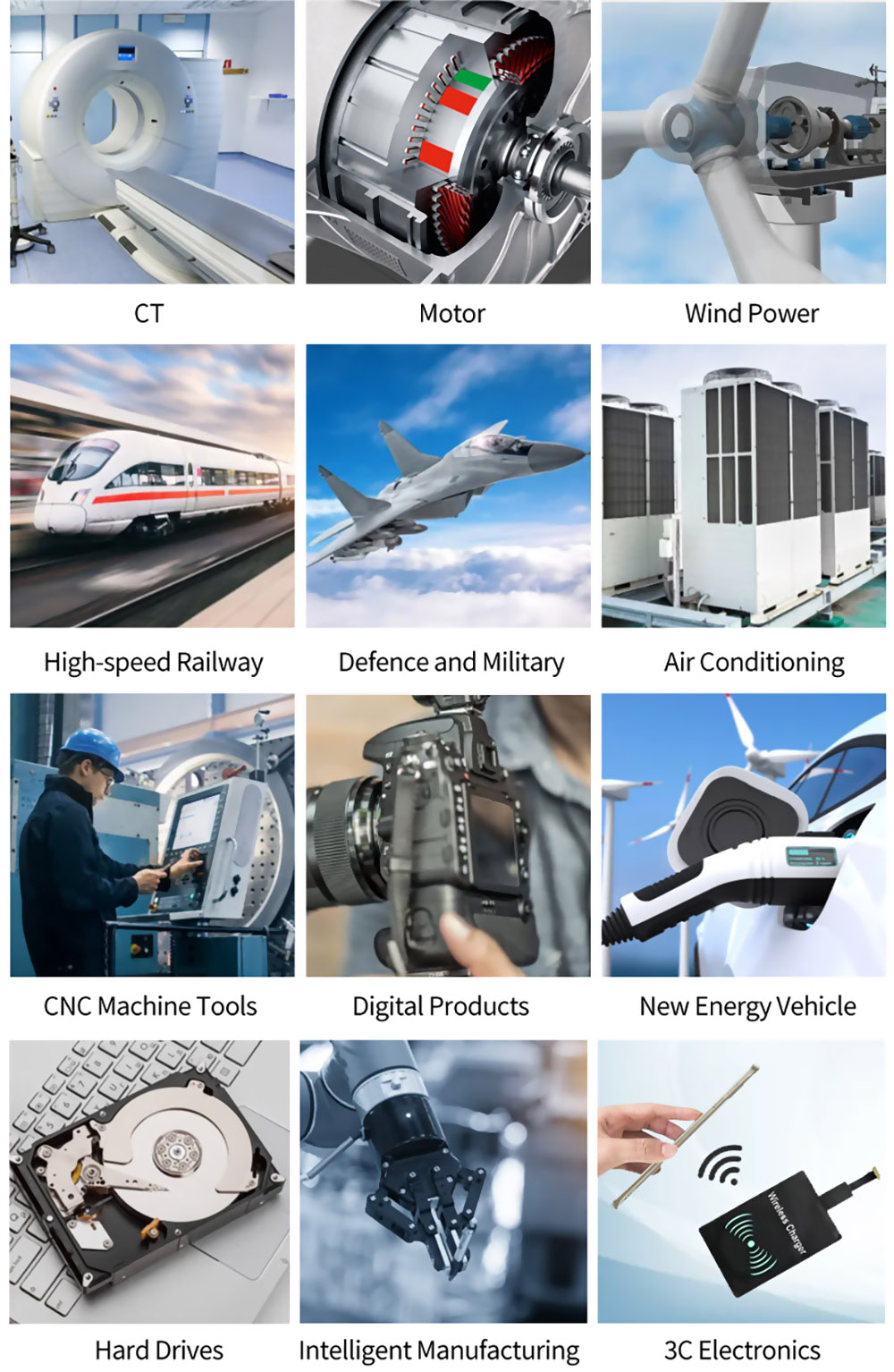

Great for Industrial Applications: Ideal for generators, motors, and other industrial equipment.

Corrosion Resistant Coating: Ni-Cu-Ni or Zn coating ensures durability and corrosion protection.

Precise Tolerance of ±1%: Guarantees accuracy and consistency in industrial applications.

Fast Delivery in 15-21 Days: Reliable and fast shipping to meet project timelines.

Advantages of Adjustable NdFeB Magnet Magnetic Square

Material: Made of high-grade NdFeB (neodymium iron boron) material, it has excellent magnetic properties and durability.

Tolerance: ±1% dimensional tolerance is available, and higher accuracy can be selected upon customer request.

Surface treatment: Zinc coating is used to enhance corrosion and oxidation resistance; gold coating is also available.

Application: Suitable for industrial use, such as magnetic hooks, magnetic bases, etc.

Advantages of Adjustable NdFeB Magnet Magnetic Square

Industrial permanent magnet motors: high-performance motors for industrial machinery.

Linear motors: used in systems that require precise linear motion.

Variable frequency compressors: ideal for efficient energy utilization in compressor applications.

Permanent magnet wind turbines: used in renewable energy power generation systems.

Railway traction motors: essential equipment for efficient power in rail transit systems.

FAQs of Adjustable NdFeB Magnet Magnetic Square

1. What materials are used for the adjustable NdFeB magnet magnetic square engineering manufacturing?

The adjustable NdFeB magnet magnetic square is made of high-quality N52 neodymium magnets, which have strong magnetism and durability.

2. Can the size and shape of the adjustable NdFeB magnet magnetic square be customized?

Yes, the product can be customized according to your specific requirements in terms of size, shape and magnetic force.

3. What is the tolerance range of the adjustable NdFeB magnet magnetic square?

The tolerance is ±1%, ensuring precision and accuracy during the manufacturing process.

4. What types of coatings are available for the adjustable NdFeB magnet magnetic square?

The magnetic square is coated with zinc to prevent corrosion, and you can also choose gold plating for additional protection.

5. Is the adjustable NdFeB magnet magnetic scale suitable for outdoor use?

Yes, the zinc coating is corrosion resistant and suitable for both indoor and outdoor use.

| Grade | Br | Hc | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ |

| min | max | min | max | min | min | min | min | min | max | min | max |

| N25 | 980 | 1020 | 9.8 | 10.2 | 8 | 637 |

|

| 22 | 27 | 175 | 215 |

| N28 | 1030 | 1070 | 10.3 | 10.7 | 8.5 | 677 |

|

| 25 | 30 | 199 | 239 |

| N30 | 1060 | 1100 | 10.6 | 11 | 9.5 | 756 |

|

| 27 | 32 | 215 | 255 |

| N33 | 1120 | 1140 | 11.2 | 11.4 | 10.5 | 836 |

|

| 30 | 35 | 239 | 279 |

| N34 | 1140 | 1170 | 11.4 | 11.7 | 11 | 876 |

|

| 31 | 36 | 247 | 287 |

| N35 | 1180 | 1220 | 11.8 | 12.2 | 12 | 955 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| N38 | 1230 | 1250 | 12.3 | 12.5 | 12 | 955 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| N40 | 1260 | 1280 | 12.6 | 12.8 | 12 | 955 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| N42 | 1290 | 1320 | 12.9 | 13.2 | 12 | 955 | 11.6 | 923 | 40 | 44 | 318 | 350 |

| N45 | 1330 | 1380 | 13.3 | 13.8 | 12 | 955 | 11.0 | 876 | 43 | 47 | 342 | 374 |

| N48 | 1370 | 1420 | 13.7 | 14.2 | 12 | 955 | 11.2 | 892 | 45 | 50 | 358 | 398 |

| N50 | 1390 | 1440 | 13.9 | 14.4 | 12 | 955 | 11.0 | 876 | 47 | 52 | 374 | 414 |

| N52 | 1420 | 1470 | 14.2 | 14.7 | 12 | 955 | 11.0 | 876 | 49 | 54 | 390 | 4.30 |

| N54 | 1450 | 1490 | 14.5 | 14.9 | 11 | 876 | 9.0 | 716 | 51 | 56 | 406 | 446 |

| N55 | 1460 | 1520 | 14.6 | 15.2 | 11 | 876 | 9.0 | 716 | 52 | 57 | 414 | 454 |

| N56 | 1470 | 1530 | 14.7 | 15.3 | 11 | 876 | 9.0 | 716 | 53 | 58 | 422 | 462 |

| N58 | 1490 | 1550 | 14.9 | 15.5 | 11 | 876 | 9.0 | 716 | 55 | 60 | 438 | 478 |

| 35M | 1180 | 1220 | 11.8 | 12.2 | 14 | 1114 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38M | 1230 | 1250 | 12.3 | 12.5 | 14 | 1114 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| 40M | 1260 | 1280 | 12.6 | 12.8 | 14 | 1114 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42M | 1290 | 1320 | 12.9 | 13.2 | 14 | 1114 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45M | 1330 | 1380 | 13.3 | 13.8 | 14 | 1114 | 12.5 | 995 | 43 | 47 | 342 | 374 |

| 48M | 1370 | 1420 | 13.7 | 14.2 | 14 | 1114 | 12.8 | 1019 | 45 | 50 | 358 | 398 |

| 50M | 1390 | 1440 | 13.9 | 14.4 | 14 | 1114 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52M | 1420 | 1470 | 14.2 | 14.7 | 13 | 1035 | 12.5 | 995 | 49 | 54 | 390 | 430 |

| 55M | 1460 | 1520 | 14.6 | 15.2 | 13 | 1035 | 12.8 | 1019 | 52 | 57 | 414 | 454 |

| 30H | 1080 | 1140 | 10.8 | 11.4 | 17 | 1353 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33H | 1140 | 1180 | 11.4 | 11.8 | 17 | 1353 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35H | 1180 | 1220 | 11.8 | 12.2 | 17 | 1353 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38H | 1230 | 1250 | 12.3 | 12.5 | 17 | 1353 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| Grade | Br | Hci | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| min | max | min | max | min | min | min | min | min | max | min | max |

| 40H | 1260 | 1280 | 12.6 | 12.8 | 17 | 1353 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42H | 1290 | 1320 | 12.9 | 13.2 | 17 | 1353 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45H | 1330 | 1380 | 13.3 | 13.8 | 17 | 1353 | 12.2 | 971 | 43 | 47 | 342 | 374 |

| 48H | 1370 | 1420 | 13.7 | 14.2 | 17 | 1353 | 12.9 | 1027 | 45 | 50 | 358 | 398 |

| 50H | 1390 | 1440 | 13.9 | 14.4 | 17 | 1353 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52H | 1420 | 1470 | 14.2 | 14.7 | 17 | 1353 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54H | 1440 | 1500 | 14.4 | 15 | 16 | 1274 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 55H | 1460 | 1520 | 14.6 | 15.2 | 16 | 1274 | 13.5 | 1075 | 52 | 57 | 414 | 454 |

| 30SH | 1080 | 1140 | 10.8 | 11.4 | 20 | 1592 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33SH | 1140 | 1170 | 11.4 | 11.7 | 20 | 1592 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35SH | 1180 | 1220 | 11.8 | 12.2 | 20 | 1592 | 11.0 | 876 | 33 | 37 | 263 | 295 |

| 38SH | 1230 | 1250 | 12.3 | 12.5 | 20 | 1592 | 11.4 | 907 | 36 | 40 | 287 | 318 |

| 40SH | 1260 | 1280 | 12.6 | 12.8 | 20 | 1592 | 11.8 | 939 | 38 | 42 | 302 | 334 |

| 42SH | 1290 | 1320 | 12.9 | 13.2 | 20 | 1592 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45SH | 1330 | 1380 | 13.3 | 13.8 | 20 | 1592 | 12.3 | 979 | 43 | 47 | 342 | 374 |

| 48SH | 1370 | 1420 | 13.7 | 14.2 | 20 | 1592 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50SH | 1390 | 1440 | 13.9 | 14.4 | 19 | 1512 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52SH | 1420 | 1470 | 14.2 | 14.7 | 19 | 1512 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54SH | 1450 | 1500 | 14.5 | 15 | 19 | 1512 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 30UH | 1080 | 1130 | 10.8 | 11.3 | 25 | 1990 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33UH | 1140 | 1170 | 11.4 | 11.7 | 25 | 1990 | 10.7 | 852 | 31 | 35 | 247 | 279 |

| 35UH | 1180 | 1220 | 11.8 | 12.2 | 25 | 1990 | 10.8 | 860 | 33 | 37 | 263 | 295 |

| 38UH | 1230 | 1250 | 12.3 | 12.5 | 25 | 1990 | 11.0 | 876 | 36 | 40 | 287 | 318 |

| 40UH | 1260 | 1280 | 12.6 | 12.8 | 25 | 1990 | 11.5 | 915 | 38 | 42 | 302 | 334 |

| 42UH | 1290 | 1330 | 12.9 | 13.3 | 25 | 1990 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45UH | 1330 | 1380 | 13.3 | 13.8 | 25 | 1990 | 12.6 | 1003 | 43 | 47 | 342 | 374 |

| 48UH | 1370 | 1420 | 13.7 | 14.2 | 24 | 1910 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50UH | 1390 | 1440 | 13.9 | 14.4 | 24 | 1910 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52UH | 1420 | 1470 | 14.2 | 14.7 | 24 | 1910 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 30EH | 1080 | 1130 | 10.8 | 11.3 | 30 | 2388 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33EH | 1140 | 1170 | 11.4 | 11.7 | 30 | 2388 | 10.3 | 820 | 31 | 35 | 247 | 279 |

| 35EH | 1180 | 1220 | 11.8 | 12.2 | 30 | 2388 | 10.5 | 836 | 33 | 37 | 263 | 295 |

| 38EH | 1220 | 1250 | 12.2 | 12.5 | 30 | 2388 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40EH | 1250 | 1280 | 12.5 | 12.8 | 30 | 2388 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42EH | 1280 | 1320 | 12.8 | 13.2 | 29 | 2308 | 12.2 | 971 | 39 | 44 | 310 | 350 |

| 45EH | 1320 | 1380 | 13.2 | 13.8 | 29 | 2308 | 12.6 | 1003 | 42 | 47 | 334 | 374 |

| 48EH | 1370 | 1420 | 13.7 | 14.2 | 29 | 2308 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50EH | 1390 | 1440 | 13.9 | 14.4 | 29 | 2308 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| Grade | Br | Hcj | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| mim | max | mm | TR | min | min | min | mim | mml | m2x | min | max |

| 28AH | 1020 | 1090 | 10.2 | 10.9 | 34 | 2760 | 9.8 | 780 | 25 | 30 | 199 | 239 |

| 30AH | 1070 | 1130 | 10.7 | 11.3 | 34 | 2760 | 10.2 | 812 | 27 | 32 | 215 | 255 |

| 33AH | 1110 | 1170 | 11.1 | 11.7 | 34 | 2706 | 10.5 | 836 | 30 | 35 | 239 | 279 |

| 35AH | 1170 | 1220 | 11.7 | 12.2 | 34 | 2706 | 10.5 | 836 | 32 | 37 | 255 | 295 |

| 38AH | 1220 | 1250 | 12.2 | 12.5 | 34 | 2706 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40AH | 1250 | 1280 | 12.5 | 12.8 | 34 | 2706 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42AH | 1280 | 1320 | 12.8 | 13.2 | 34 | 2706 | 12.2 | 971 | 39 | 44 | 310 | 350 |