Corrosion Resistant Hetero magnetic NdFeB magnet is a highly specialized neodymium magnet with unique properties. Unlike conventional magnets, it is composed of different magnetic regions or materials, which allows for a more complex magnetic field distribution. This makes it ideal for applications that require customized magnetic strength and direction.

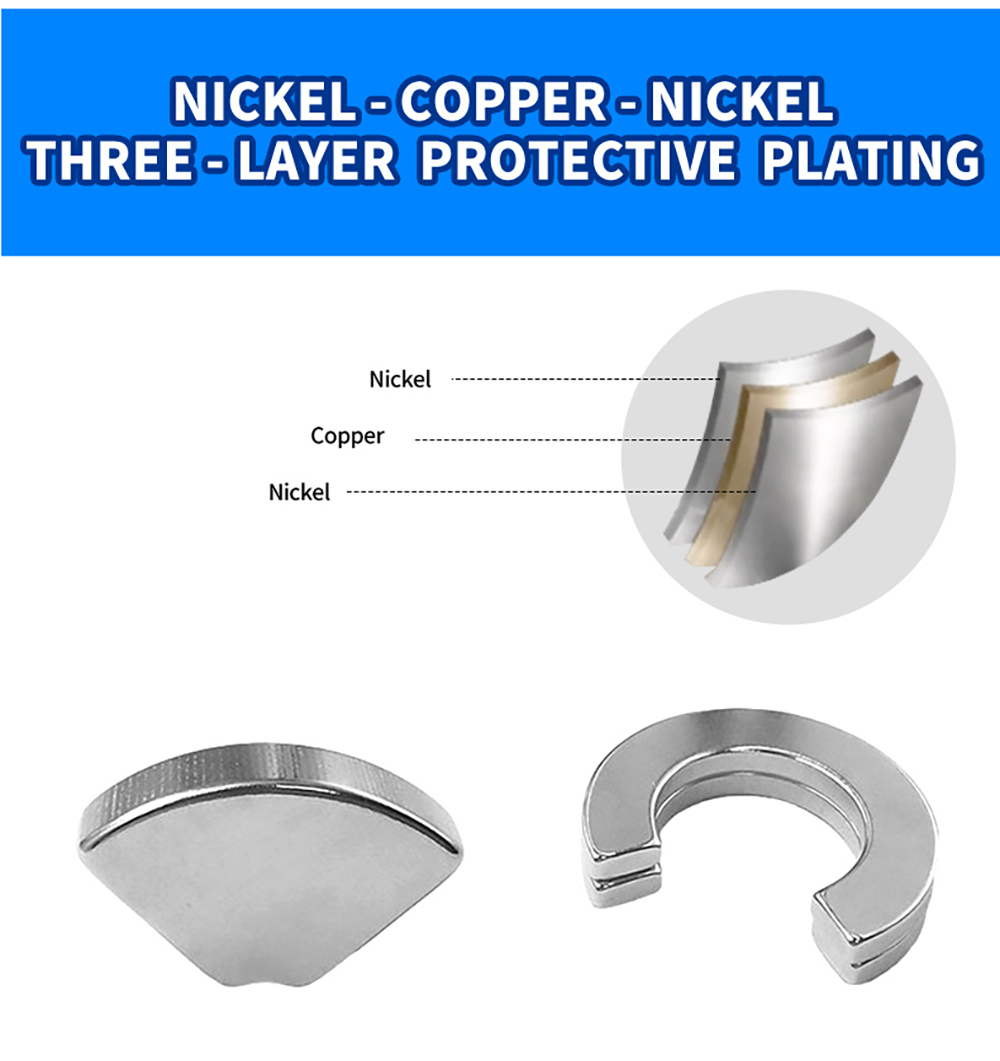

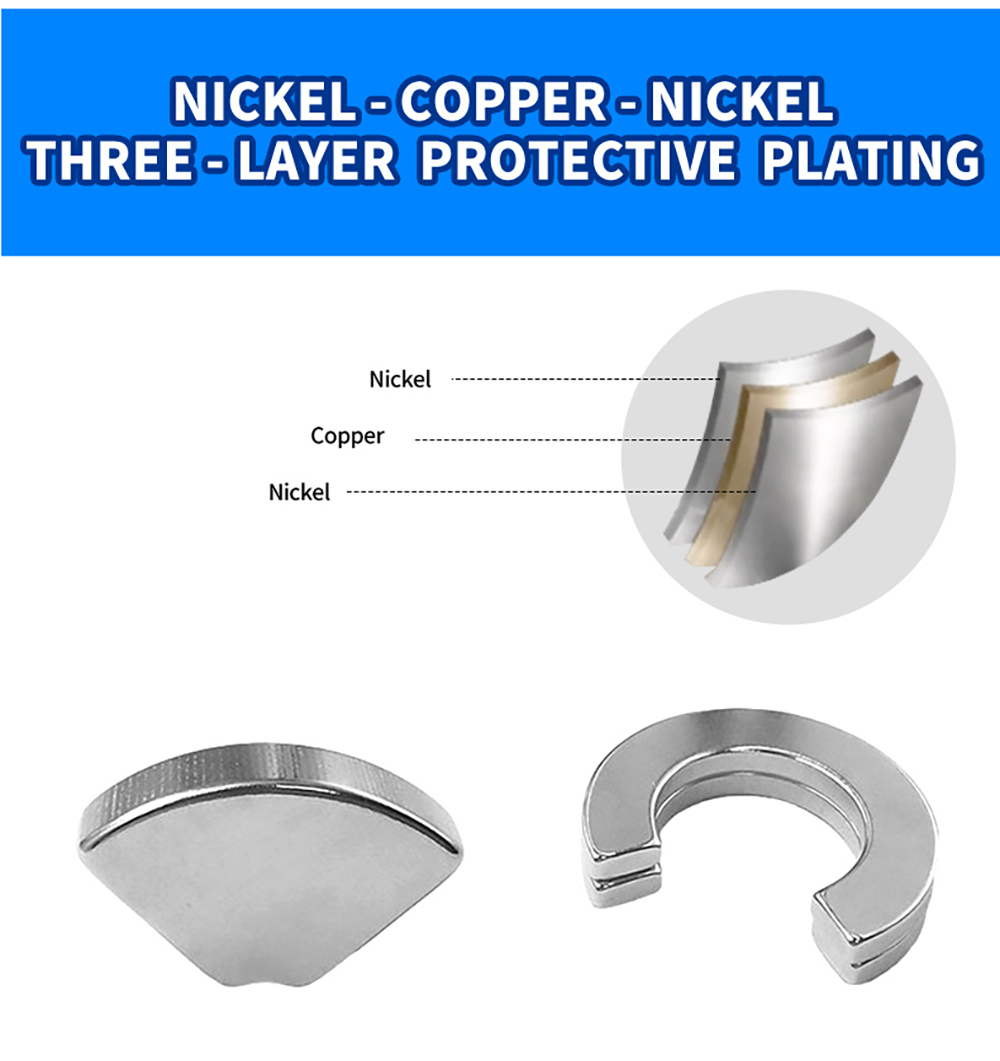

These magnets are designed for high performance and durability. The NdFeB material provides strong magnetic force, while corrosion-resistant coatings such as Ni-Cu-Ni, Zn, and epoxy ensure long life and reliability even in challenging environments. The magnets can be made into a variety of shapes, including discs, blocks, rings, and arcs, allowing for flexibility in a wide range of industrial applications.

With tolerances of ±1%, these magnets are very precise, ensuring consistent performance in demanding environments. They are available in grades ranging from N35 to N52, offering different levels of magnetic strength options. Whether used in motors, generators, or other industrial machinery, these magnets meet the most stringent requirements.

Corrosion Resistant Hetero magnetic NdFeB magnets are a custom-engineered solution that combines high performance, reliability, and versatility, making them an essential component in many industrial applications.

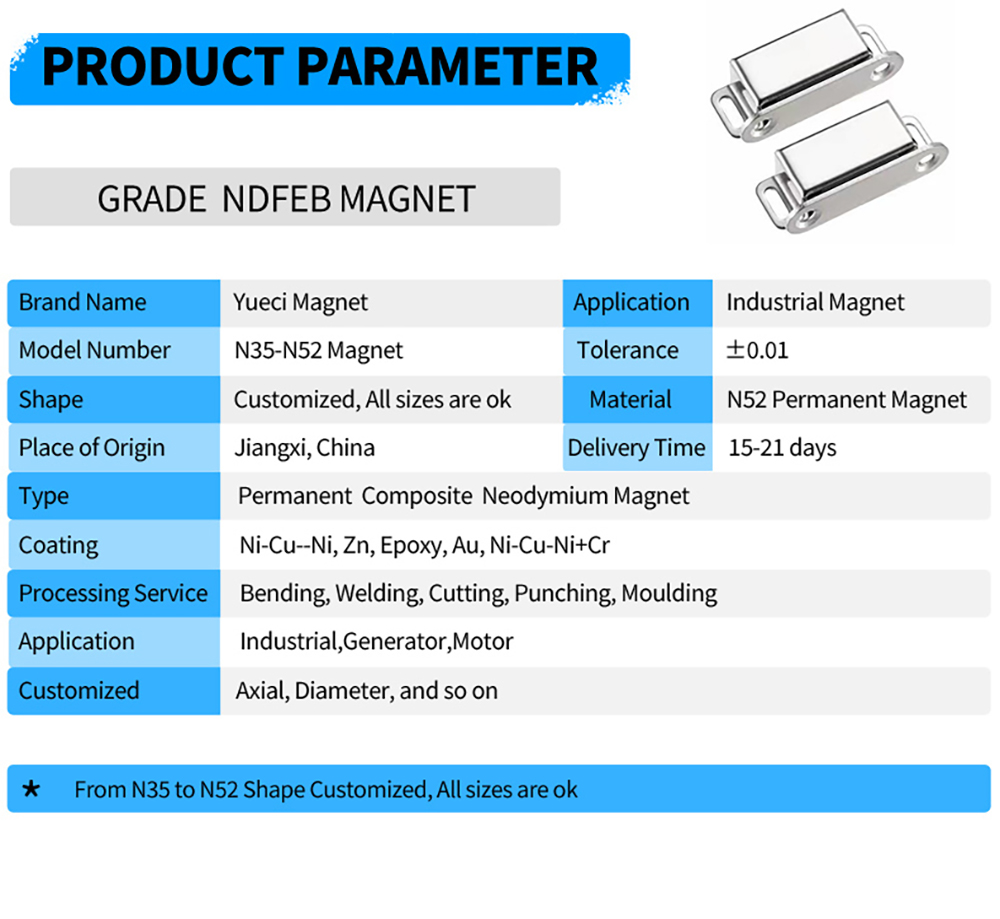

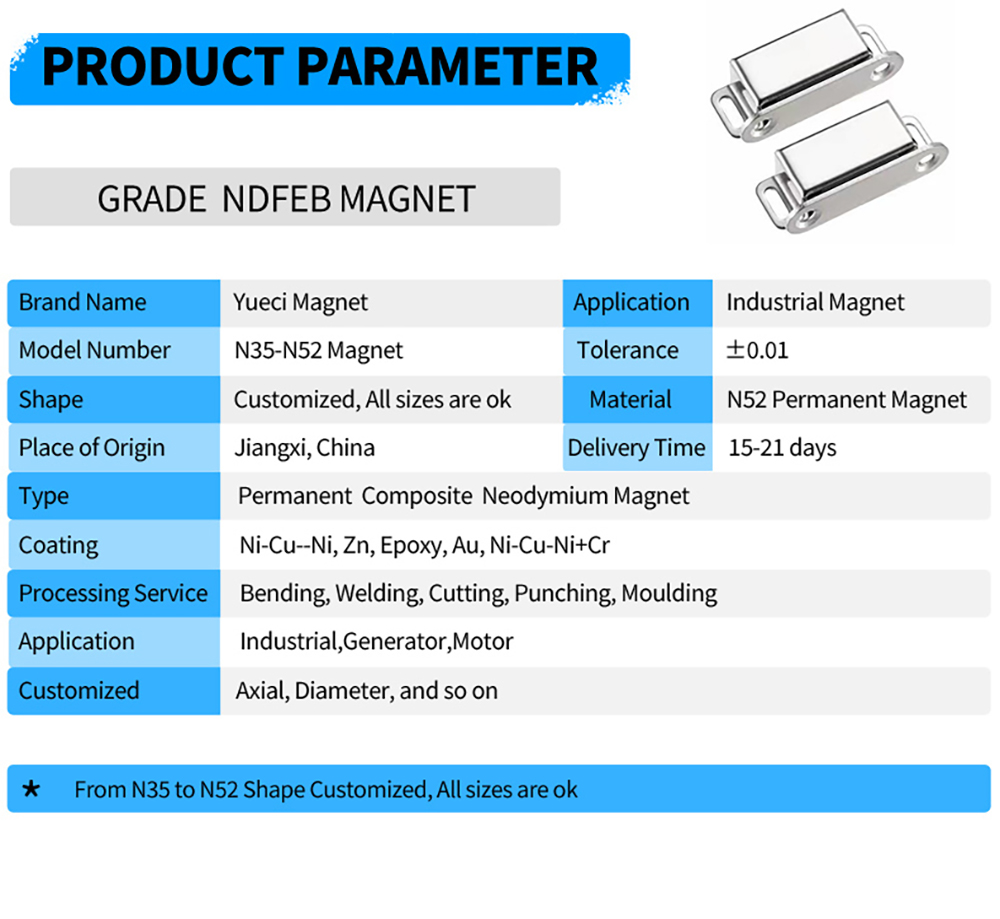

Parameter Table

| Parameter | Value |

| Tolerance | ±1% |

| Grade | NdFeB Magnet |

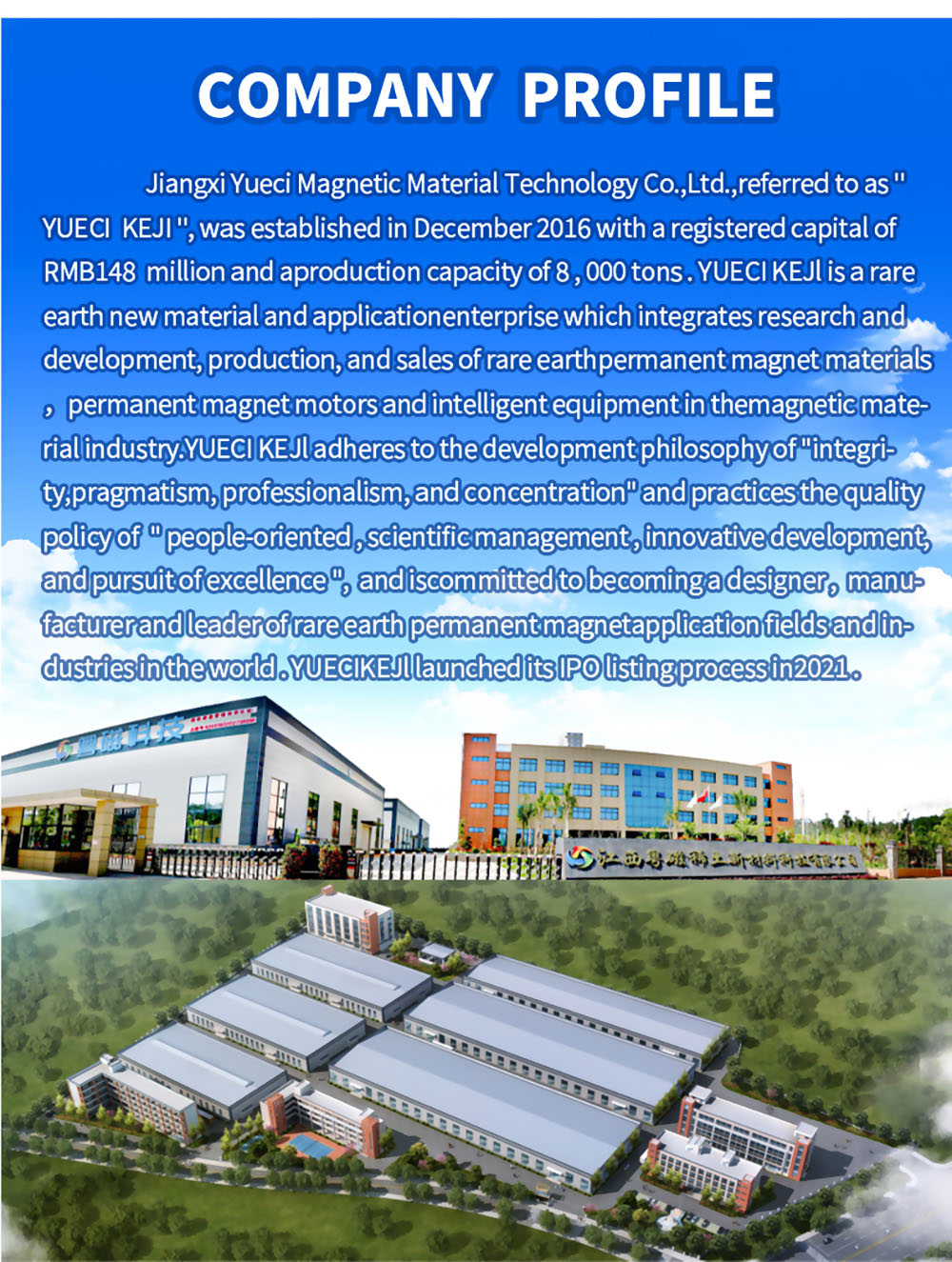

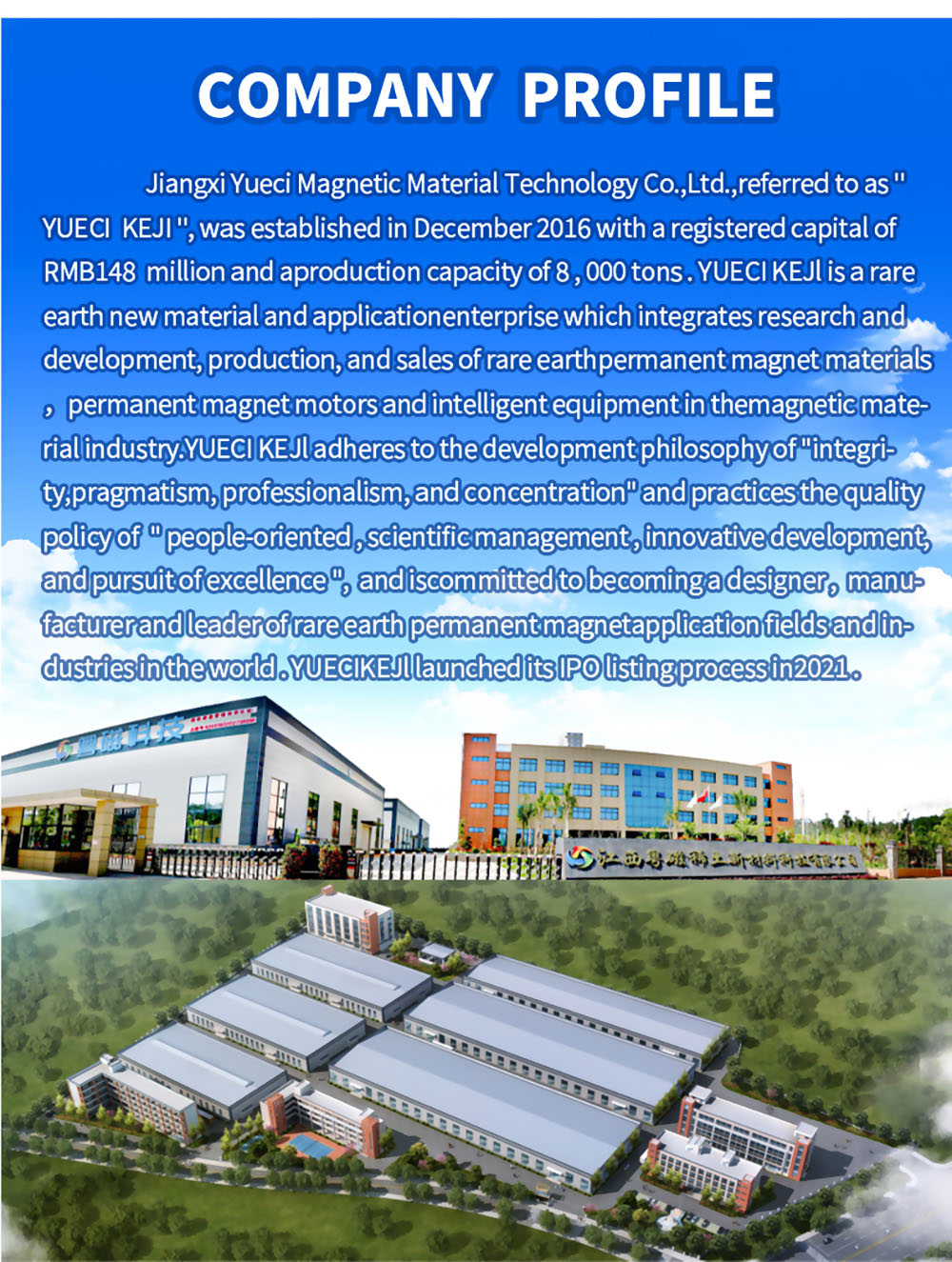

| Place of Origin | Jiangxi, China |

| Delivery Time | 15-21 days |

| Brand Name | Yueci |

| Model Number | N35-N52 Magnet |

| Type | Permanent |

| Composite | Neodymium Magnet |

| Shape | Disc, Block, Ring, Arc, Customized |

| Application | Industrial, Generator, Motor |

| Processing Service | Bending, Welding, Cutting, Punching, Moulding |

| Certification | ISO9001:2008, ISO/TS16949:2009, RoHS |

| Founded | Since 2012 |

| Material | N52 Permanent Magnet |

| Grade | Customized, From N35 to N52 |

| Coating | Ni-Cu-Ni, Zn, Epoxy, Au, Ni-Cu-Ni+Cr |

| Magnetic Force | Customized |

| Magnetization Direction | Customized, Axial, Diameter, etc. |

Features of Corrosion-Resistant Hetero Magnetic NdFeB Magnet

Diverse Magnetic Properties: The anisotropic design combines different magnetic materials to provide a variety of magnetic field characteristics for various applications.

Efficient Magnetic Field Distribution: Achieve complex magnetic field distribution, with better flexibility and performance than uniform magnets.

Strong and Durable: Made of high-quality materials to ensure long-lasting durability and stable performance in various environments.

Wide Application Range: Suitable for industrial equipment, medical equipment, magnetic levitation, magnetic separation, etc. to meet specific magnetic needs.

Advantages of Corrosion Resistant Hetero magnetic NdFeB Magnets

Custom Design:

Tailored to user specifications for a wide range of industrial applications.

Premium Magnet:

N52 grade ensures strong magnetic force and performance reliability.

Durable Construction:

Made of high-quality Neodymium Iron Boron (NdFeB), it is corrosion and wear resistant for long-term use.

ISO 9001:2000 Certified Quality:

Products meet international quality standards, ensuring reliability and safety.

Application Scenarios of Corrosion Resistant Hetero magnetic NdFeB Magnets

Industrial Applications:

Used in magnetic separation and suspension systems to improve the efficiency and precision of industrial processes.

Medical Equipment:

Provides precise magnetic field control in instruments such as MRI machines for accurate imaging.

R&D:

Supports advanced scientific research and technology development to explore new magnetic materials and their applications.

FAQs of Corrosion-Resistant Hetero Magnetic NdFeB Magnet

1. What are the main features of Corrosion Resistant Heteromagnetic NdFeB Magnets?

Diversification of magnetic properties through different magnetic materials.

Highly efficient magnetic field distribution for greater application flexibility.

High durability and stability under different environmental conditions.

Wide range of applications, including industrial and medical uses.

2. How is this magnet different from ordinary NdFeB magnets?

Unlike conventional uniform NdFeB magnets, Heteromagnetic magnets combine different magnetic materials. This results in more diverse magnetic field properties and better performance in complex applications.

3. What industries can benefit from using these magnets?

These magnets are widely used in industrial processes such as magnetic separation, magnetic levitation, medical devices, and scientific research and development.

4. Can these magnets be customized?

Yes, these magnets can be customized in shape, size, and magnetic force, making them suitable for specific industrial and scientific applications.

5. Can Corrosion Resistant Heteromagnetic NdFeB Magnets be used in medical devices?

Yes, it is ideal for use in medical devices that require precise magnetic fields, such as MRI machines.

| Grade | Br | Hc | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ |

| min | max | min | max | min | min | min | min | min | max | min | max |

| N25 | 980 | 1020 | 9.8 | 10.2 | 8 | 637 |

|

| 22 | 27 | 175 | 215 |

| N28 | 1030 | 1070 | 10.3 | 10.7 | 8.5 | 677 |

|

| 25 | 30 | 199 | 239 |

| N30 | 1060 | 1100 | 10.6 | 11 | 9.5 | 756 |

|

| 27 | 32 | 215 | 255 |

| N33 | 1120 | 1140 | 11.2 | 11.4 | 10.5 | 836 |

|

| 30 | 35 | 239 | 279 |

| N34 | 1140 | 1170 | 11.4 | 11.7 | 11 | 876 |

|

| 31 | 36 | 247 | 287 |

| N35 | 1180 | 1220 | 11.8 | 12.2 | 12 | 955 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| N38 | 1230 | 1250 | 12.3 | 12.5 | 12 | 955 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| N40 | 1260 | 1280 | 12.6 | 12.8 | 12 | 955 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| N42 | 1290 | 1320 | 12.9 | 13.2 | 12 | 955 | 11.6 | 923 | 40 | 44 | 318 | 350 |

| N45 | 1330 | 1380 | 13.3 | 13.8 | 12 | 955 | 11.0 | 876 | 43 | 47 | 342 | 374 |

| N48 | 1370 | 1420 | 13.7 | 14.2 | 12 | 955 | 11.2 | 892 | 45 | 50 | 358 | 398 |

| N50 | 1390 | 1440 | 13.9 | 14.4 | 12 | 955 | 11.0 | 876 | 47 | 52 | 374 | 414 |

| N52 | 1420 | 1470 | 14.2 | 14.7 | 12 | 955 | 11.0 | 876 | 49 | 54 | 390 | 4.30 |

| N54 | 1450 | 1490 | 14.5 | 14.9 | 11 | 876 | 9.0 | 716 | 51 | 56 | 406 | 446 |

| N55 | 1460 | 1520 | 14.6 | 15.2 | 11 | 876 | 9.0 | 716 | 52 | 57 | 414 | 454 |

| N56 | 1470 | 1530 | 14.7 | 15.3 | 11 | 876 | 9.0 | 716 | 53 | 58 | 422 | 462 |

| N58 | 1490 | 1550 | 14.9 | 15.5 | 11 | 876 | 9.0 | 716 | 55 | 60 | 438 | 478 |

| 35M | 1180 | 1220 | 11.8 | 12.2 | 14 | 1114 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38M | 1230 | 1250 | 12.3 | 12.5 | 14 | 1114 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| 40M | 1260 | 1280 | 12.6 | 12.8 | 14 | 1114 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42M | 1290 | 1320 | 12.9 | 13.2 | 14 | 1114 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45M | 1330 | 1380 | 13.3 | 13.8 | 14 | 1114 | 12.5 | 995 | 43 | 47 | 342 | 374 |

| 48M | 1370 | 1420 | 13.7 | 14.2 | 14 | 1114 | 12.8 | 1019 | 45 | 50 | 358 | 398 |

| 50M | 1390 | 1440 | 13.9 | 14.4 | 14 | 1114 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52M | 1420 | 1470 | 14.2 | 14.7 | 13 | 1035 | 12.5 | 995 | 49 | 54 | 390 | 430 |

| 55M | 1460 | 1520 | 14.6 | 15.2 | 13 | 1035 | 12.8 | 1019 | 52 | 57 | 414 | 454 |

| 30H | 1080 | 1140 | 10.8 | 11.4 | 17 | 1353 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33H | 1140 | 1180 | 11.4 | 11.8 | 17 | 1353 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35H | 1180 | 1220 | 11.8 | 12.2 | 17 | 1353 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38H | 1230 | 1250 | 12.3 | 12.5 | 17 | 1353 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| Grade | Br | Hci | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| min | max | min | max | min | min | min | min | min | max | min | max |

| 40H | 1260 | 1280 | 12.6 | 12.8 | 17 | 1353 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42H | 1290 | 1320 | 12.9 | 13.2 | 17 | 1353 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45H | 1330 | 1380 | 13.3 | 13.8 | 17 | 1353 | 12.2 | 971 | 43 | 47 | 342 | 374 |

| 48H | 1370 | 1420 | 13.7 | 14.2 | 17 | 1353 | 12.9 | 1027 | 45 | 50 | 358 | 398 |

| 50H | 1390 | 1440 | 13.9 | 14.4 | 17 | 1353 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52H | 1420 | 1470 | 14.2 | 14.7 | 17 | 1353 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54H | 1440 | 1500 | 14.4 | 15 | 16 | 1274 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 55H | 1460 | 1520 | 14.6 | 15.2 | 16 | 1274 | 13.5 | 1075 | 52 | 57 | 414 | 454 |

| 30SH | 1080 | 1140 | 10.8 | 11.4 | 20 | 1592 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33SH | 1140 | 1170 | 11.4 | 11.7 | 20 | 1592 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35SH | 1180 | 1220 | 11.8 | 12.2 | 20 | 1592 | 11.0 | 876 | 33 | 37 | 263 | 295 |

| 38SH | 1230 | 1250 | 12.3 | 12.5 | 20 | 1592 | 11.4 | 907 | 36 | 40 | 287 | 318 |

| 40SH | 1260 | 1280 | 12.6 | 12.8 | 20 | 1592 | 11.8 | 939 | 38 | 42 | 302 | 334 |

| 42SH | 1290 | 1320 | 12.9 | 13.2 | 20 | 1592 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45SH | 1330 | 1380 | 13.3 | 13.8 | 20 | 1592 | 12.3 | 979 | 43 | 47 | 342 | 374 |

| 48SH | 1370 | 1420 | 13.7 | 14.2 | 20 | 1592 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50SH | 1390 | 1440 | 13.9 | 14.4 | 19 | 1512 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52SH | 1420 | 1470 | 14.2 | 14.7 | 19 | 1512 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54SH | 1450 | 1500 | 14.5 | 15 | 19 | 1512 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 30UH | 1080 | 1130 | 10.8 | 11.3 | 25 | 1990 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33UH | 1140 | 1170 | 11.4 | 11.7 | 25 | 1990 | 10.7 | 852 | 31 | 35 | 247 | 279 |

| 35UH | 1180 | 1220 | 11.8 | 12.2 | 25 | 1990 | 10.8 | 860 | 33 | 37 | 263 | 295 |

| 38UH | 1230 | 1250 | 12.3 | 12.5 | 25 | 1990 | 11.0 | 876 | 36 | 40 | 287 | 318 |

| 40UH | 1260 | 1280 | 12.6 | 12.8 | 25 | 1990 | 11.5 | 915 | 38 | 42 | 302 | 334 |

| 42UH | 1290 | 1330 | 12.9 | 13.3 | 25 | 1990 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45UH | 1330 | 1380 | 13.3 | 13.8 | 25 | 1990 | 12.6 | 1003 | 43 | 47 | 342 | 374 |

| 48UH | 1370 | 1420 | 13.7 | 14.2 | 24 | 1910 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50UH | 1390 | 1440 | 13.9 | 14.4 | 24 | 1910 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52UH | 1420 | 1470 | 14.2 | 14.7 | 24 | 1910 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 30EH | 1080 | 1130 | 10.8 | 11.3 | 30 | 2388 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33EH | 1140 | 1170 | 11.4 | 11.7 | 30 | 2388 | 10.3 | 820 | 31 | 35 | 247 | 279 |

| 35EH | 1180 | 1220 | 11.8 | 12.2 | 30 | 2388 | 10.5 | 836 | 33 | 37 | 263 | 295 |

| 38EH | 1220 | 1250 | 12.2 | 12.5 | 30 | 2388 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40EH | 1250 | 1280 | 12.5 | 12.8 | 30 | 2388 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42EH | 1280 | 1320 | 12.8 | 13.2 | 29 | 2308 | 12.2 | 971 | 39 | 44 | 310 | 350 |

| 45EH | 1320 | 1380 | 13.2 | 13.8 | 29 | 2308 | 12.6 | 1003 | 42 | 47 | 334 | 374 |

| 48EH | 1370 | 1420 | 13.7 | 14.2 | 29 | 2308 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50EH | 1390 | 1440 | 13.9 | 14.4 | 29 | 2308 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| Grade | Br | Hcj | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| mim | max | mm | TR | min | min | min | mim | mml | m2x | min | max |

| 28AH | 1020 | 1090 | 10.2 | 10.9 | 34 | 2760 | 9.8 | 780 | 25 | 30 | 199 | 239 |

| 30AH | 1070 | 1130 | 10.7 | 11.3 | 34 | 2760 | 10.2 | 812 | 27 | 32 | 215 | 255 |

| 33AH | 1110 | 1170 | 11.1 | 11.7 | 34 | 2706 | 10.5 | 836 | 30 | 35 | 239 | 279 |

| 35AH | 1170 | 1220 | 11.7 | 12.2 | 34 | 2706 | 10.5 | 836 | 32 | 37 | 255 | 295 |

| 38AH | 1220 | 1250 | 12.2 | 12.5 | 34 | 2706 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40AH | 1250 | 1280 | 12.5 | 12.8 | 34 | 2706 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42AH | 1280 | 1320 | 12.8 | 13.2 | 34 | 2706 | 12.2 | 971 | 39 | 44 | 310 | 350 |