High coercivity NdFeB neodymium bar magnet is designed for magnetic separators. It is made of NdFeB (neodymium, iron, boron) magnets encapsulated in stainless steel tubes. These magnetic bars are effective in removing iron impurities and metal particles from raw materials.

The magnets are assembled, welded and polished to ensure high performance. They are suitable for applications that require strong and durable magnets to filter metal contaminants.

NdFeB magnetic bars are available with customizable magnetic strengths based on customer needs. Whether it is ferrite magnets or high-performance NdFeB magnets, we can produce magnetic bars that meet specific surface magnetic force requirements.

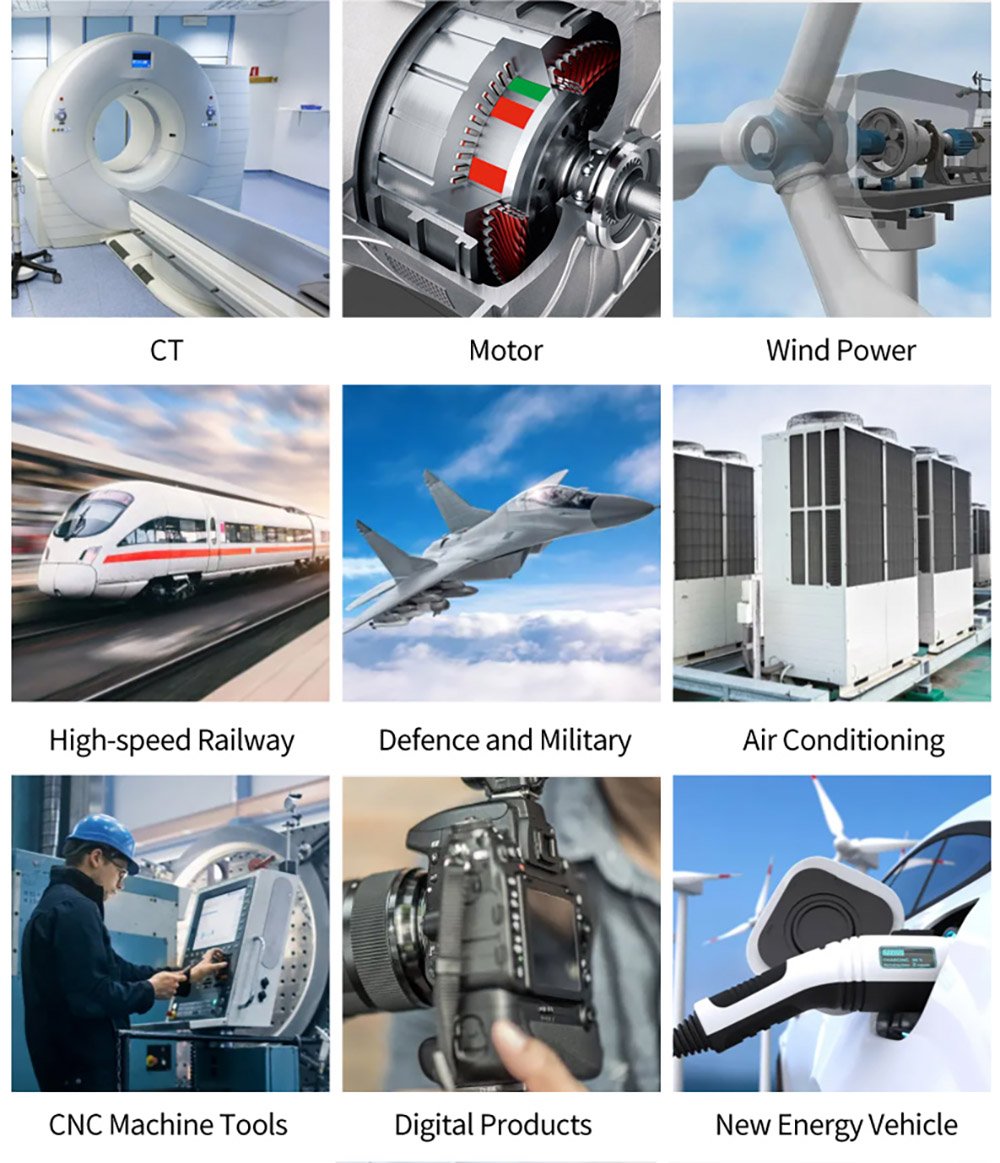

These magnetic bars are widely used in industries such as food processing, pharmaceuticals, and recycling. They are ideal for applications involving loose or flowing raw materials. NdFeB magnetic bars are highly efficient in extracting iron and metal particles, which improves the purity of the final product.

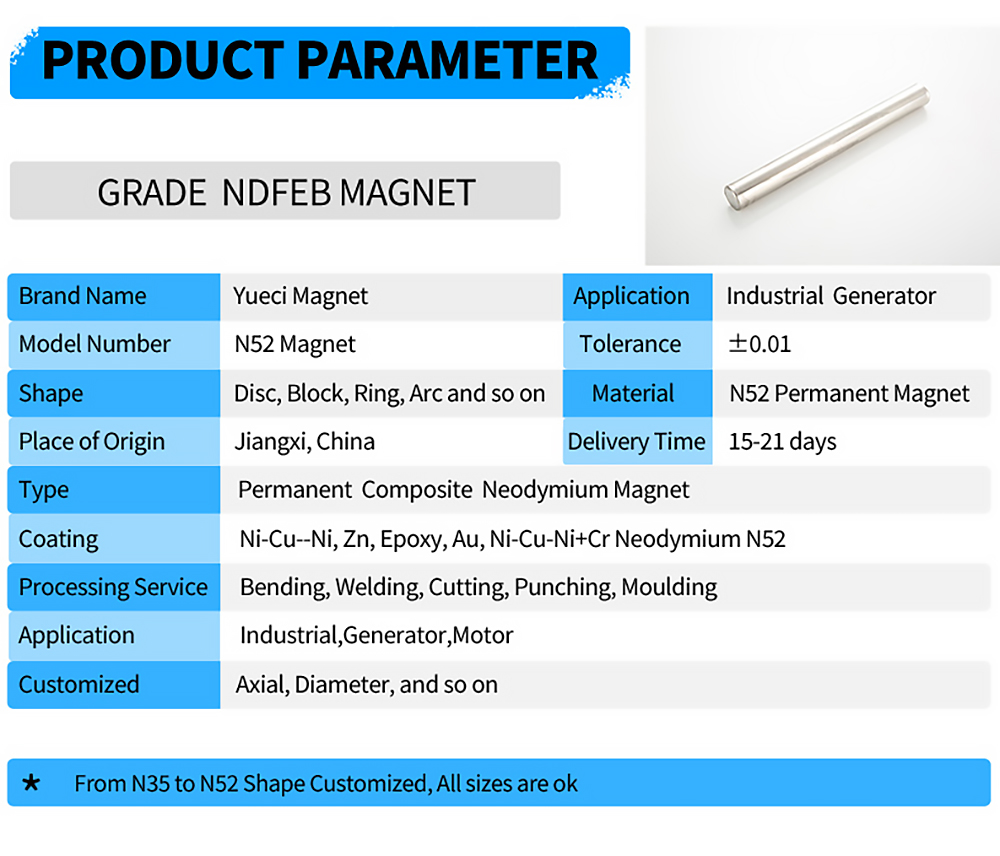

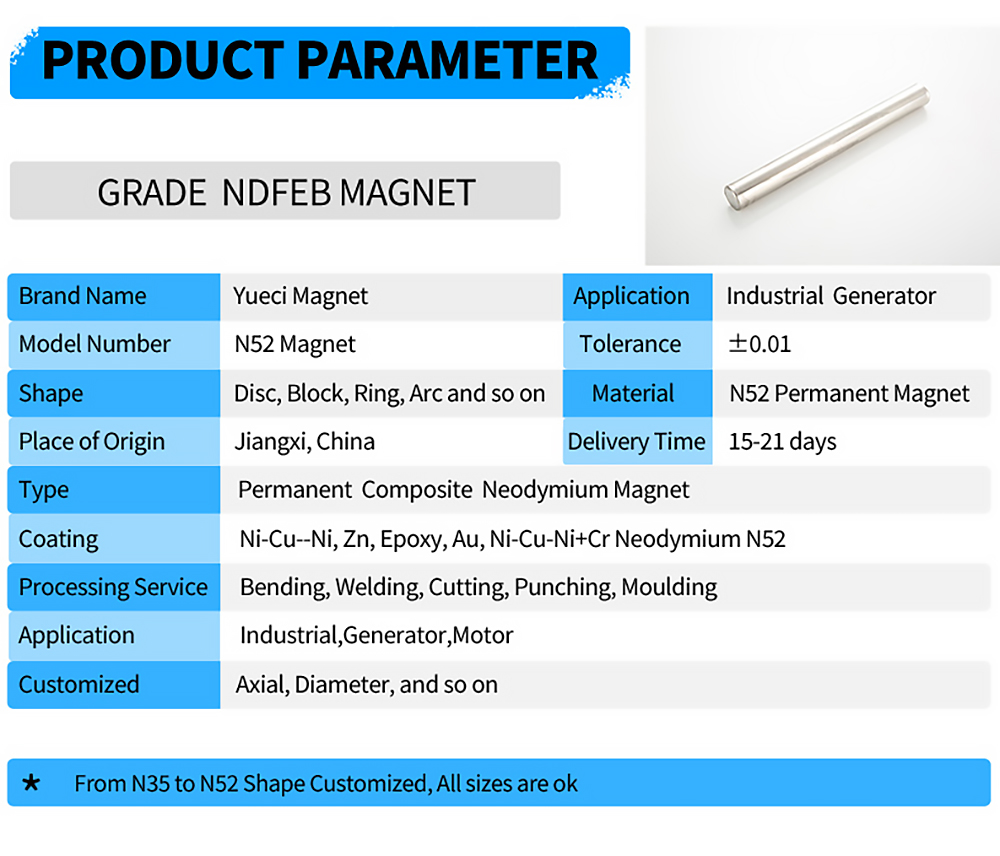

Product Parameters Table

| Parameter | Value |

| Tolerance | ±1% |

| Grade | NdFeB Magnet |

| Place of Origin | Jiangxi, China |

| Delivery Time | 15-21 days |

| Brand Name | Yueci |

| Model Number | N52 Magnet |

| Type | Permanent |

| Composite | Neodymium Magnet |

| Shape | Disc, Block, Ring, Arc, and more |

| Application | Industrial Magnet |

| Processing Service | Bending, Welding, Cutting, Punching, Moulding |

| Certification | ISO9001:2008, ISO/TS16949:2009, RoHS |

| Material | N52 Permanent Magnet |

| Grade | Customized, From N35 to N52 |

| Shape | Customized, All sizes available |

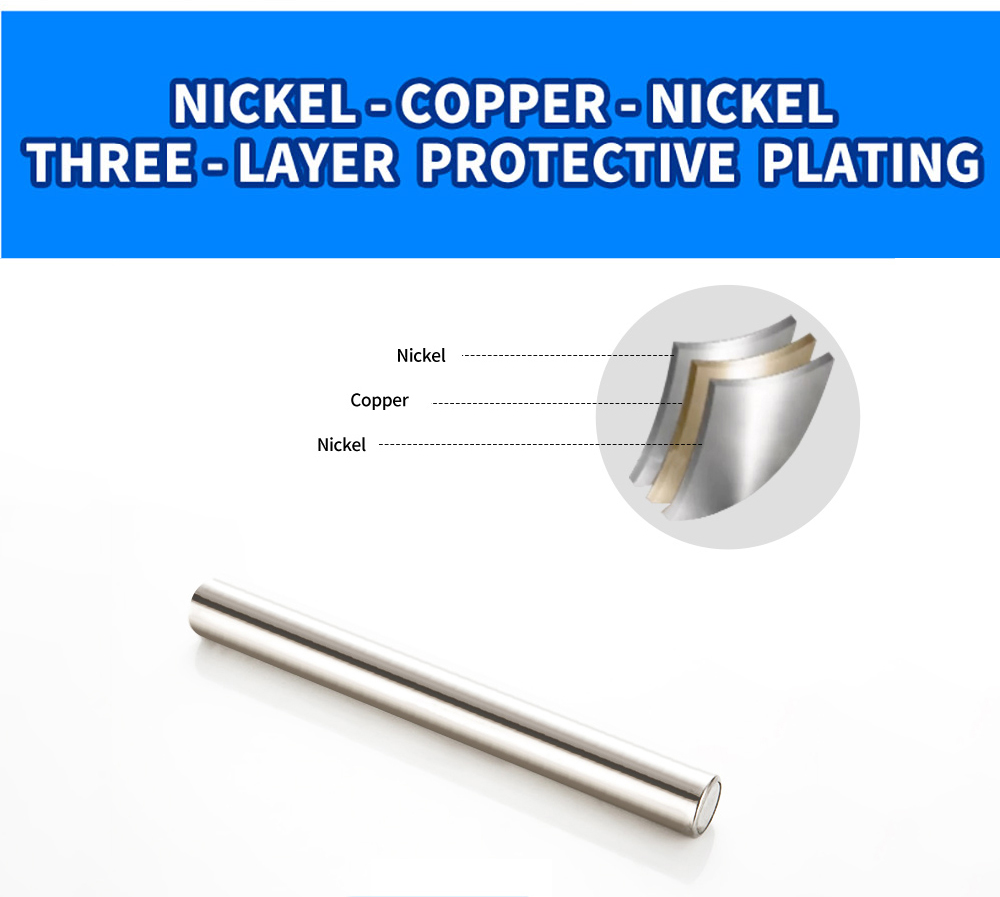

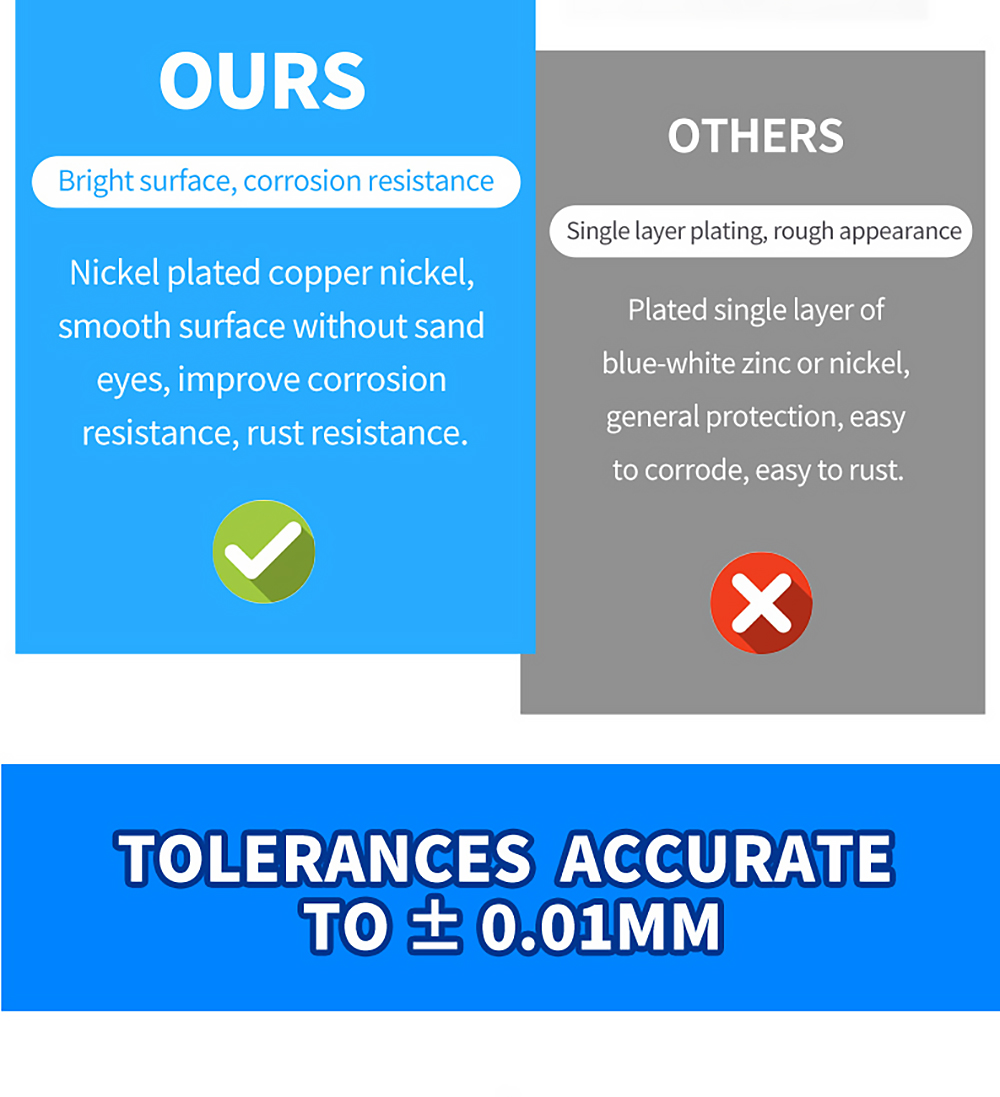

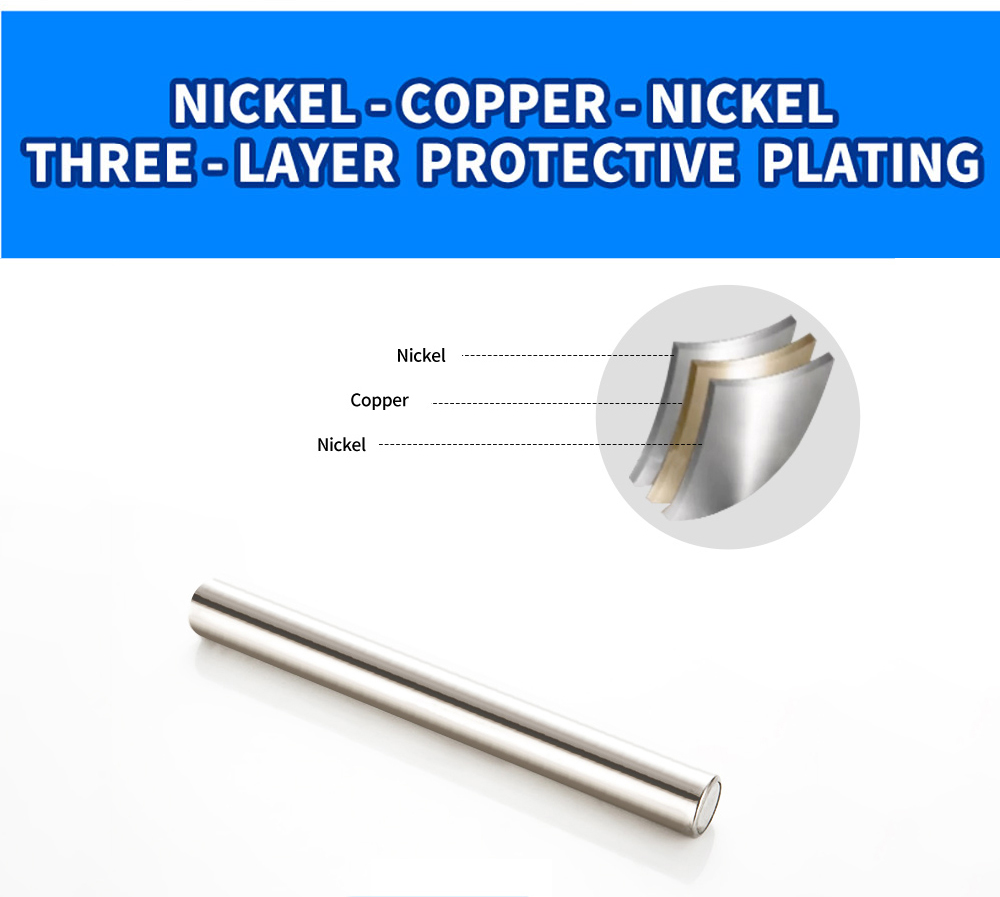

| Coating | Ni-Cu-Ni, Zn, Epoxy, Au, Ni-Cu-Ni+Cr |

| Magnetic Force | Customized |

| Magnetization Direction | Customized, Axial, Diameter, etc. |

Features of High Coercivity NdFeB Bar Neodymium Magnets

Easy to disassemble and clean:

The design allows simple disassembly and cleaning, ensuring easy maintenance.

No energy consumption, zero pollution:

The magnets do not consume energy and produce no pollution when in operation, promoting sustainable development.

High efficiency and stability:

Stable magnetic force and excellent performance during long-term use.

Flexible design and production applications:

Can be customized according to specific customer needs and application requirements.

Use of high-performance NdFeB magnets:

Made of NdFeB magnets for maximum strength and reliability.

Surface magnetic force up to 12000-14000 Gauss:

The magnetic bar can achieve high surface magnetic force, improving its efficiency in removing metal contaminants.

Advantages of High Coercivity NdFeB Bar Neodymium Magnet

Custom Designs:

Tailored to specific customer needs for a wide range of industrial applications.

Premium Magnets:

Made with N52 grade NdFeB magnets for strong magnetic force and reliable performance.

Durable Construction:

Made with premium NdFeB material, it is resistant to corrosion and wear, ensuring long-term durability.

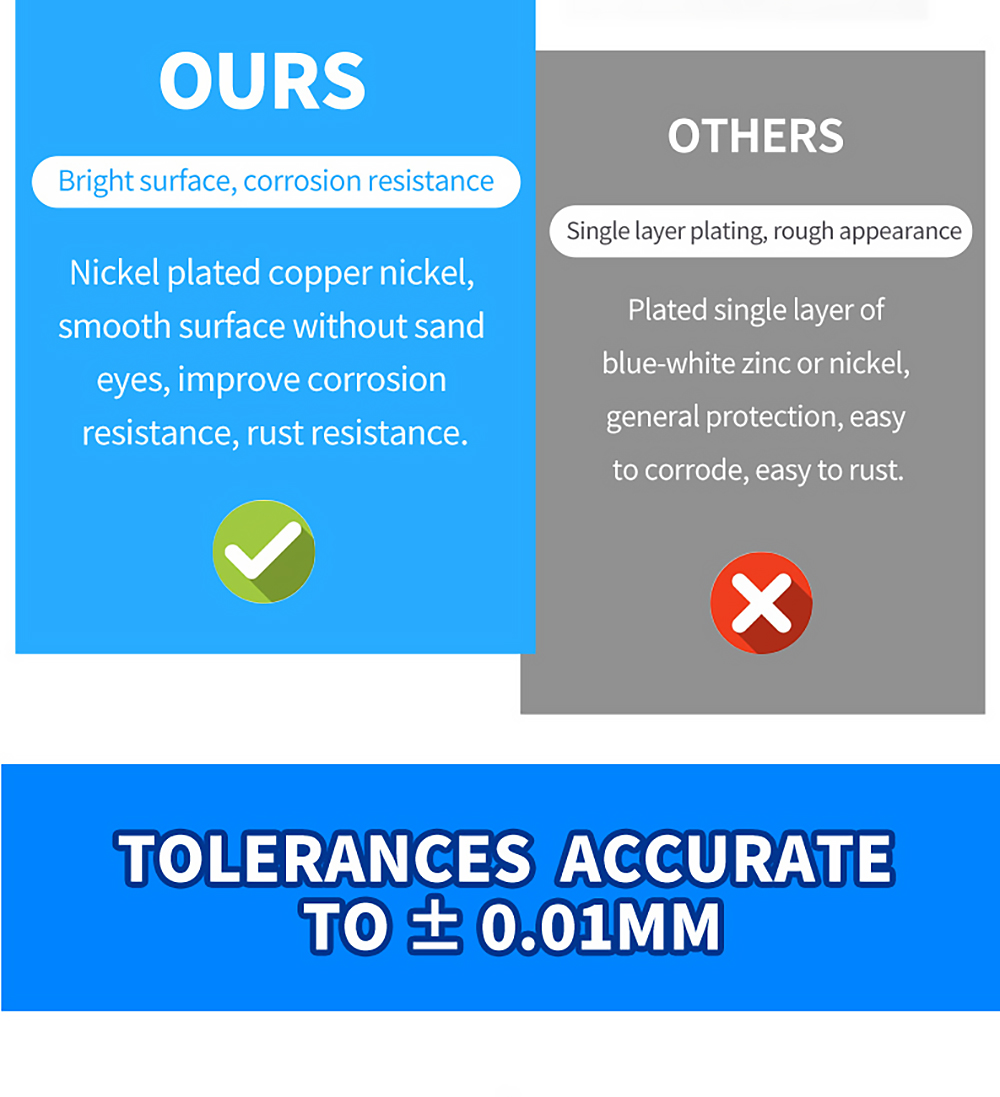

Precise Tolerances:

Tolerances of ±0.05mm ensure precise alignment and consistent performance in demanding industrial environments.

ISO 9001:2000 Certified Quality:

Compliant with international standards, ensuring reliable, high-quality performance.

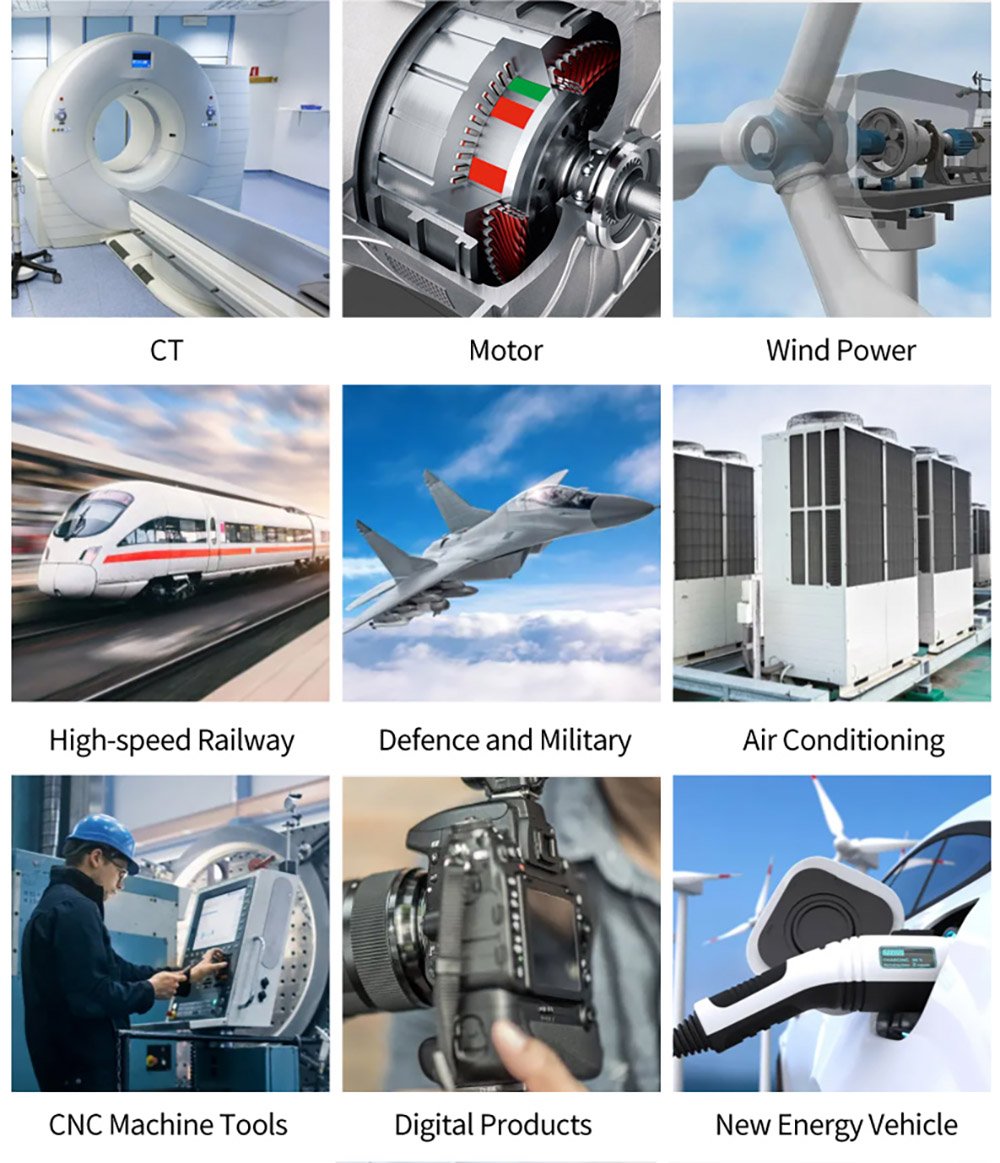

Application scenarios of High Coercivity NdFeB Bar Neodymium Magnet

Food processing:

Effectively remove iron impurities from raw materials to ensure product safety and quality.

Agricultural and sideline product processing:

Used to separate metal contaminants from agricultural products and improve purity.

Pharmaceutical industry:

It is essential for magnetic separation and filtration to remove metal particles to maintain high product standards.

Magnetic separation and filtration:

It is essential to improve material quality by removing iron and metal contaminants in various industrial processes.

FAQs of High Coercivity NdFeB Bar Neodymium Magnet

1. What is the magnetic strength of NdFeB rod magnets?

The surface magnetic force of these rods can reach 12,000–14,000 Gauss, ensuring effective magnetic separation.

2. How to ensure proper maintenance of NdFeB rod magnets?

These magnets are designed to be easily disassembled and cleaned, ensuring minimal maintenance while providing maximum efficiency.

3. Can you provide OEM/ODM services for custom applications?

Yes, we provide complete OEM/ODM services, including design, customization, and production to your specific needs.

4. How long is the delivery time for these magnet rods?

Delivery usually takes 15-21 days, depending on the order volume and customization requirements.

5. Are the magnets corrosion resistant?

Yes, NdFeB rods are plated with durable materials such as Ni-Cu-Ni or Zn to enhance corrosion resistance.

| Grade | Br | Hc | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ |

| min | max | min | max | min | min | min | min | min | max | min | max |

| N25 | 980 | 1020 | 9.8 | 10.2 | 8 | 637 |

|

| 22 | 27 | 175 | 215 |

| N28 | 1030 | 1070 | 10.3 | 10.7 | 8.5 | 677 |

|

| 25 | 30 | 199 | 239 |

| N30 | 1060 | 1100 | 10.6 | 11 | 9.5 | 756 |

|

| 27 | 32 | 215 | 255 |

| N33 | 1120 | 1140 | 11.2 | 11.4 | 10.5 | 836 |

|

| 30 | 35 | 239 | 279 |

| N34 | 1140 | 1170 | 11.4 | 11.7 | 11 | 876 |

|

| 31 | 36 | 247 | 287 |

| N35 | 1180 | 1220 | 11.8 | 12.2 | 12 | 955 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| N38 | 1230 | 1250 | 12.3 | 12.5 | 12 | 955 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| N40 | 1260 | 1280 | 12.6 | 12.8 | 12 | 955 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| N42 | 1290 | 1320 | 12.9 | 13.2 | 12 | 955 | 11.6 | 923 | 40 | 44 | 318 | 350 |

| N45 | 1330 | 1380 | 13.3 | 13.8 | 12 | 955 | 11.0 | 876 | 43 | 47 | 342 | 374 |

| N48 | 1370 | 1420 | 13.7 | 14.2 | 12 | 955 | 11.2 | 892 | 45 | 50 | 358 | 398 |

| N50 | 1390 | 1440 | 13.9 | 14.4 | 12 | 955 | 11.0 | 876 | 47 | 52 | 374 | 414 |

| N52 | 1420 | 1470 | 14.2 | 14.7 | 12 | 955 | 11.0 | 876 | 49 | 54 | 390 | 4.30 |

| N54 | 1450 | 1490 | 14.5 | 14.9 | 11 | 876 | 9.0 | 716 | 51 | 56 | 406 | 446 |

| N55 | 1460 | 1520 | 14.6 | 15.2 | 11 | 876 | 9.0 | 716 | 52 | 57 | 414 | 454 |

| N56 | 1470 | 1530 | 14.7 | 15.3 | 11 | 876 | 9.0 | 716 | 53 | 58 | 422 | 462 |

| N58 | 1490 | 1550 | 14.9 | 15.5 | 11 | 876 | 9.0 | 716 | 55 | 60 | 438 | 478 |

| 35M | 1180 | 1220 | 11.8 | 12.2 | 14 | 1114 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38M | 1230 | 1250 | 12.3 | 12.5 | 14 | 1114 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| 40M | 1260 | 1280 | 12.6 | 12.8 | 14 | 1114 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42M | 1290 | 1320 | 12.9 | 13.2 | 14 | 1114 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45M | 1330 | 1380 | 13.3 | 13.8 | 14 | 1114 | 12.5 | 995 | 43 | 47 | 342 | 374 |

| 48M | 1370 | 1420 | 13.7 | 14.2 | 14 | 1114 | 12.8 | 1019 | 45 | 50 | 358 | 398 |

| 50M | 1390 | 1440 | 13.9 | 14.4 | 14 | 1114 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52M | 1420 | 1470 | 14.2 | 14.7 | 13 | 1035 | 12.5 | 995 | 49 | 54 | 390 | 430 |

| 55M | 1460 | 1520 | 14.6 | 15.2 | 13 | 1035 | 12.8 | 1019 | 52 | 57 | 414 | 454 |

| 30H | 1080 | 1140 | 10.8 | 11.4 | 17 | 1353 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33H | 1140 | 1180 | 11.4 | 11.8 | 17 | 1353 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35H | 1180 | 1220 | 11.8 | 12.2 | 17 | 1353 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38H | 1230 | 1250 | 12.3 | 12.5 | 17 | 1353 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| Grade | Br | Hci | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| min | max | min | max | min | min | min | min | min | max | min | max |

| 40H | 1260 | 1280 | 12.6 | 12.8 | 17 | 1353 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42H | 1290 | 1320 | 12.9 | 13.2 | 17 | 1353 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45H | 1330 | 1380 | 13.3 | 13.8 | 17 | 1353 | 12.2 | 971 | 43 | 47 | 342 | 374 |

| 48H | 1370 | 1420 | 13.7 | 14.2 | 17 | 1353 | 12.9 | 1027 | 45 | 50 | 358 | 398 |

| 50H | 1390 | 1440 | 13.9 | 14.4 | 17 | 1353 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52H | 1420 | 1470 | 14.2 | 14.7 | 17 | 1353 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54H | 1440 | 1500 | 14.4 | 15 | 16 | 1274 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 55H | 1460 | 1520 | 14.6 | 15.2 | 16 | 1274 | 13.5 | 1075 | 52 | 57 | 414 | 454 |

| 30SH | 1080 | 1140 | 10.8 | 11.4 | 20 | 1592 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33SH | 1140 | 1170 | 11.4 | 11.7 | 20 | 1592 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35SH | 1180 | 1220 | 11.8 | 12.2 | 20 | 1592 | 11.0 | 876 | 33 | 37 | 263 | 295 |

| 38SH | 1230 | 1250 | 12.3 | 12.5 | 20 | 1592 | 11.4 | 907 | 36 | 40 | 287 | 318 |

| 40SH | 1260 | 1280 | 12.6 | 12.8 | 20 | 1592 | 11.8 | 939 | 38 | 42 | 302 | 334 |

| 42SH | 1290 | 1320 | 12.9 | 13.2 | 20 | 1592 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45SH | 1330 | 1380 | 13.3 | 13.8 | 20 | 1592 | 12.3 | 979 | 43 | 47 | 342 | 374 |

| 48SH | 1370 | 1420 | 13.7 | 14.2 | 20 | 1592 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50SH | 1390 | 1440 | 13.9 | 14.4 | 19 | 1512 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52SH | 1420 | 1470 | 14.2 | 14.7 | 19 | 1512 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54SH | 1450 | 1500 | 14.5 | 15 | 19 | 1512 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 30UH | 1080 | 1130 | 10.8 | 11.3 | 25 | 1990 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33UH | 1140 | 1170 | 11.4 | 11.7 | 25 | 1990 | 10.7 | 852 | 31 | 35 | 247 | 279 |

| 35UH | 1180 | 1220 | 11.8 | 12.2 | 25 | 1990 | 10.8 | 860 | 33 | 37 | 263 | 295 |

| 38UH | 1230 | 1250 | 12.3 | 12.5 | 25 | 1990 | 11.0 | 876 | 36 | 40 | 287 | 318 |

| 40UH | 1260 | 1280 | 12.6 | 12.8 | 25 | 1990 | 11.5 | 915 | 38 | 42 | 302 | 334 |

| 42UH | 1290 | 1330 | 12.9 | 13.3 | 25 | 1990 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45UH | 1330 | 1380 | 13.3 | 13.8 | 25 | 1990 | 12.6 | 1003 | 43 | 47 | 342 | 374 |

| 48UH | 1370 | 1420 | 13.7 | 14.2 | 24 | 1910 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50UH | 1390 | 1440 | 13.9 | 14.4 | 24 | 1910 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52UH | 1420 | 1470 | 14.2 | 14.7 | 24 | 1910 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 30EH | 1080 | 1130 | 10.8 | 11.3 | 30 | 2388 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33EH | 1140 | 1170 | 11.4 | 11.7 | 30 | 2388 | 10.3 | 820 | 31 | 35 | 247 | 279 |

| 35EH | 1180 | 1220 | 11.8 | 12.2 | 30 | 2388 | 10.5 | 836 | 33 | 37 | 263 | 295 |

| 38EH | 1220 | 1250 | 12.2 | 12.5 | 30 | 2388 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40EH | 1250 | 1280 | 12.5 | 12.8 | 30 | 2388 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42EH | 1280 | 1320 | 12.8 | 13.2 | 29 | 2308 | 12.2 | 971 | 39 | 44 | 310 | 350 |

| 45EH | 1320 | 1380 | 13.2 | 13.8 | 29 | 2308 | 12.6 | 1003 | 42 | 47 | 334 | 374 |

| 48EH | 1370 | 1420 | 13.7 | 14.2 | 29 | 2308 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50EH | 1390 | 1440 | 13.9 | 14.4 | 29 | 2308 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| Grade | Br | Hcj | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| mim | max | mm | TR | min | min | min | mim | mml | m2x | min | max |

| 28AH | 1020 | 1090 | 10.2 | 10.9 | 34 | 2760 | 9.8 | 780 | 25 | 30 | 199 | 239 |

| 30AH | 1070 | 1130 | 10.7 | 11.3 | 34 | 2760 | 10.2 | 812 | 27 | 32 | 215 | 255 |

| 33AH | 1110 | 1170 | 11.1 | 11.7 | 34 | 2706 | 10.5 | 836 | 30 | 35 | 239 | 279 |

| 35AH | 1170 | 1220 | 11.7 | 12.2 | 34 | 2706 | 10.5 | 836 | 32 | 37 | 255 | 295 |

| 38AH | 1220 | 1250 | 12.2 | 12.5 | 34 | 2706 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40AH | 1250 | 1280 | 12.5 | 12.8 | 34 | 2706 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42AH | 1280 | 1320 | 12.8 | 13.2 | 34 | 2706 | 12.2 | 971 | 39 | 44 | 310 | 350 |