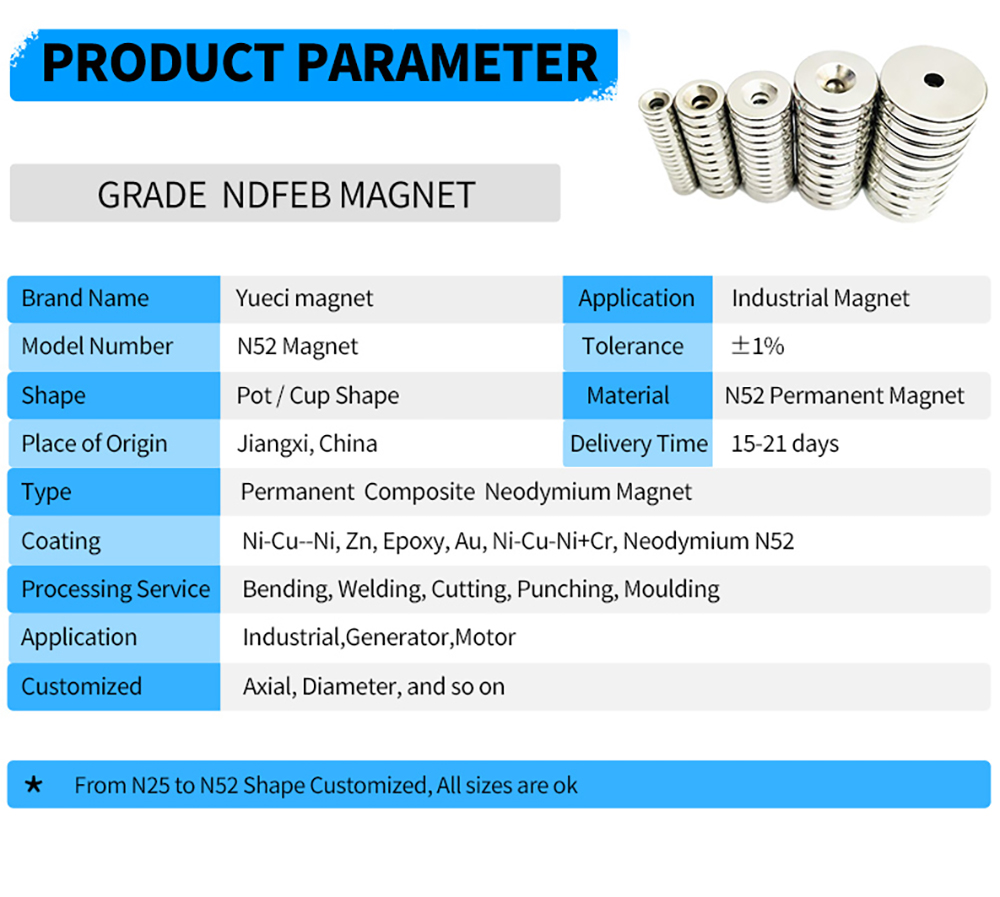

The Diameter Magnetized NdFeB Ring Magnet is a high-performance magnet designed specifically for audio equipment. Manufactured by Yueci, this magnet features superior magnetic strength and reliability, making it ideal for applications that require precision and stability.

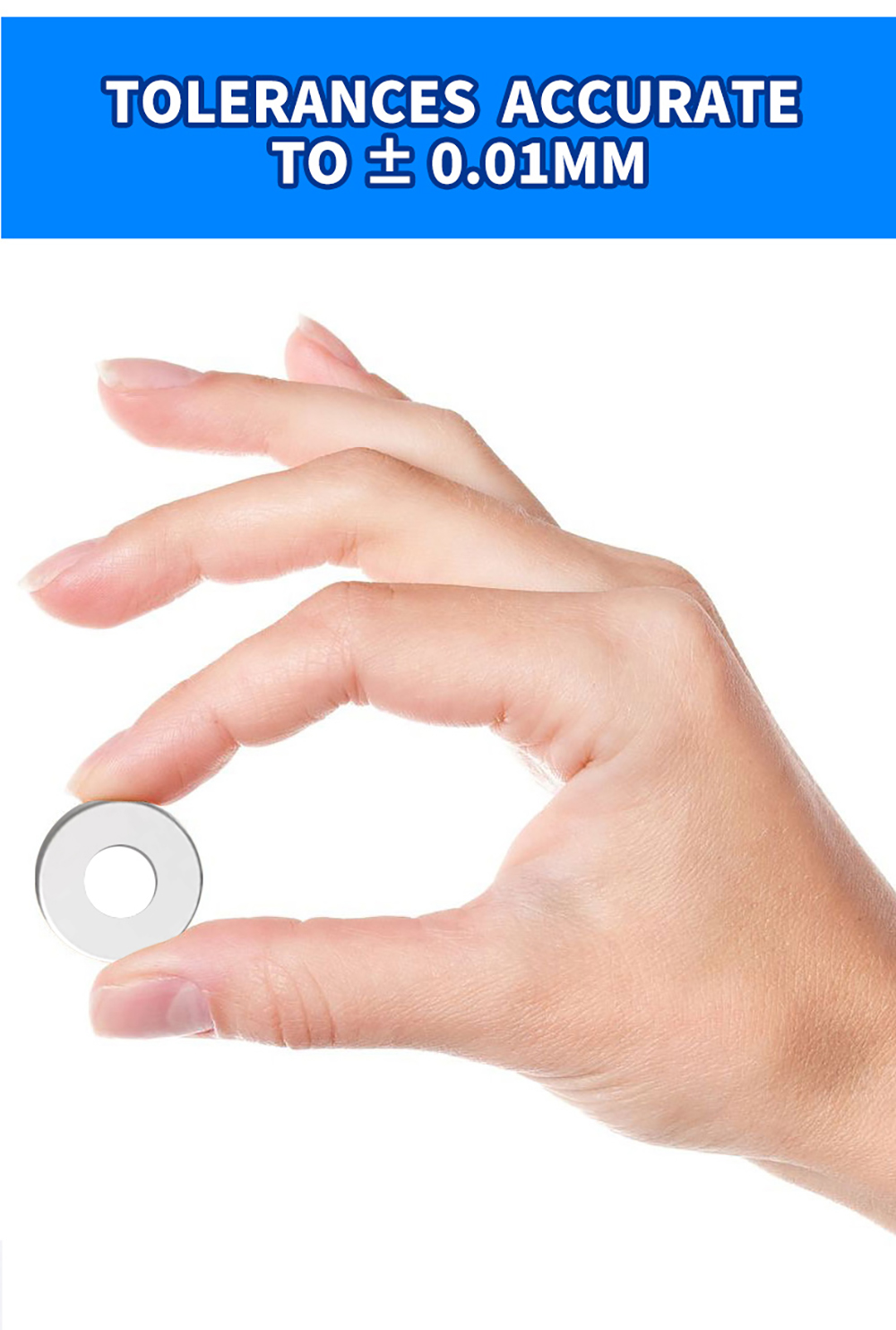

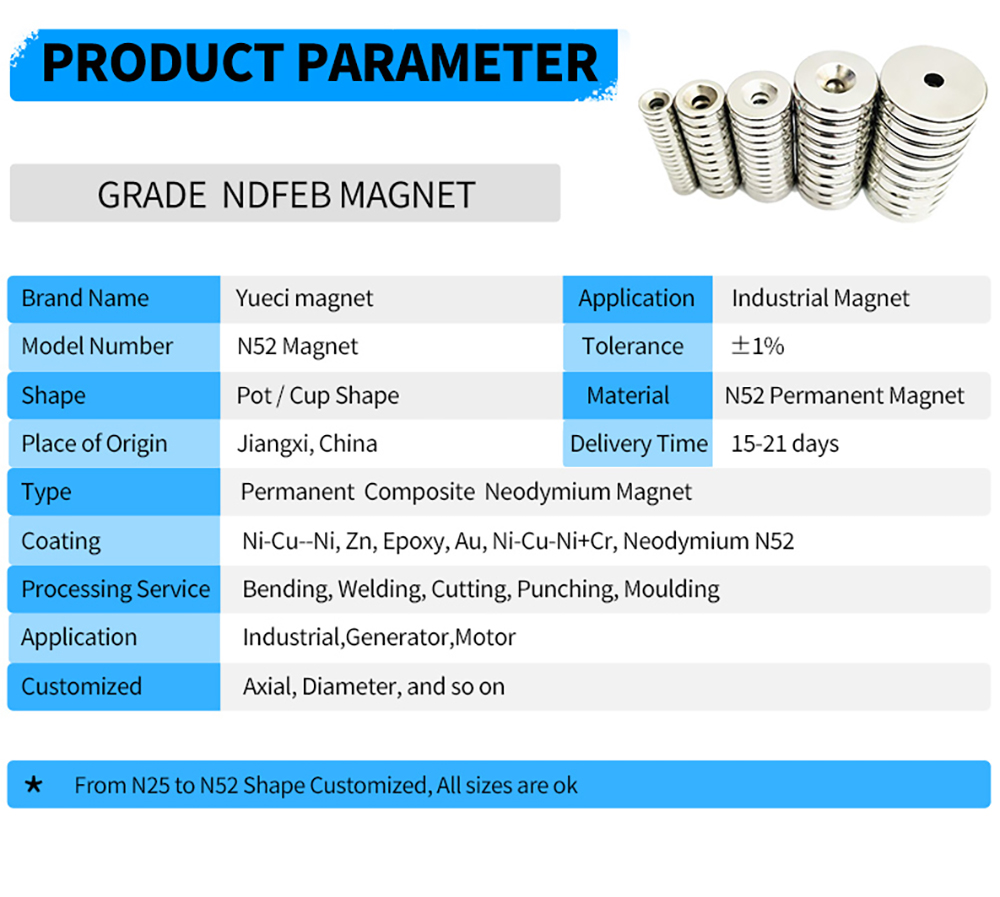

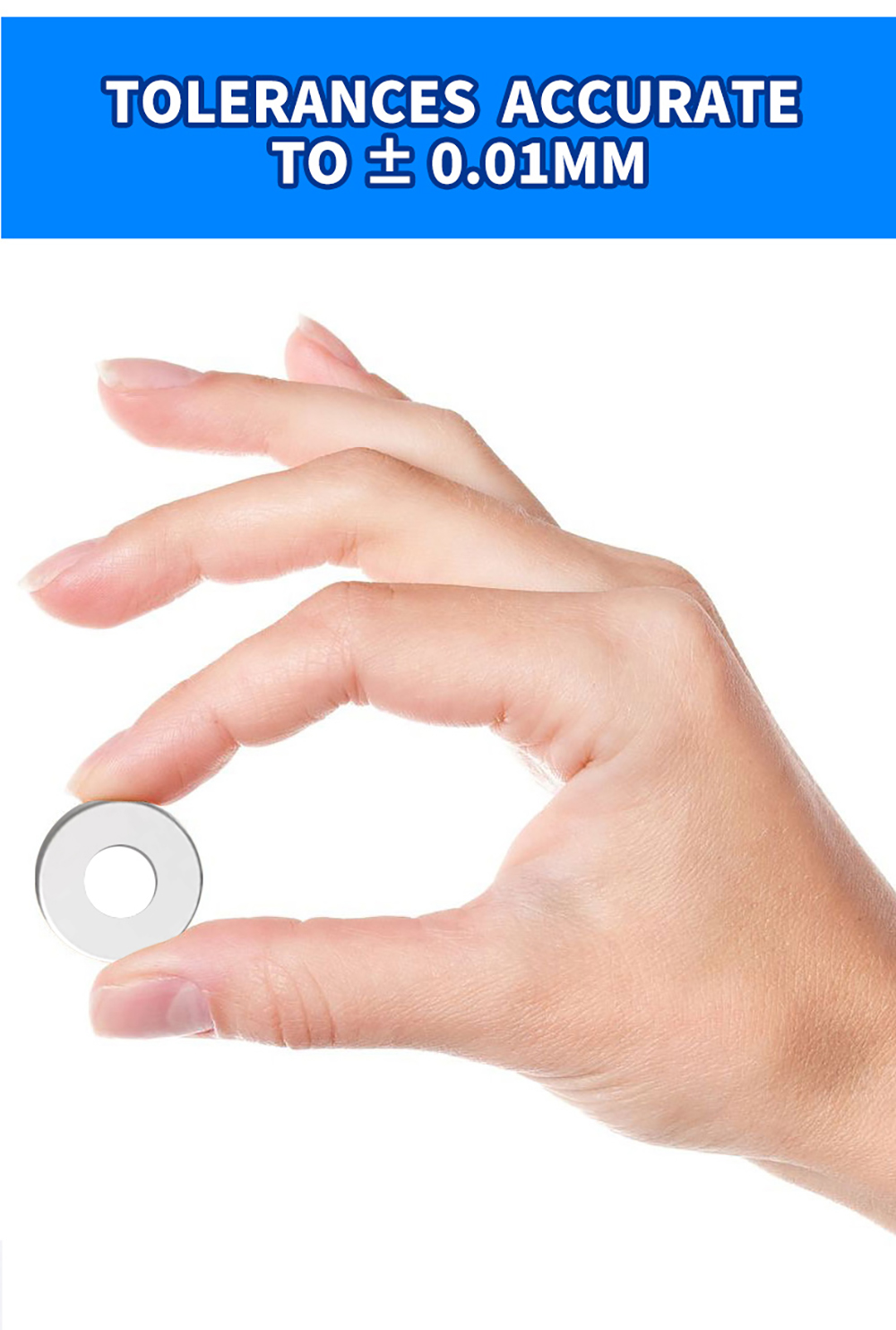

These magnets are available in a variety of grades, from N35 to N52, ensuring you can choose the right strength for your application. With a tolerance of ±1%, you can be confident in the consistency and quality of each magnet.

The Diameter Magnetized NdFeB Ring Magnet can be customized to your exact specifications. Its magnetization direction is flexible, allowing you to choose axial, diameter, or other configurations as needed.

We also offer a variety of coating options to protect the magnet from corrosion and ensure long-lasting performance. Coating options include Ni-Cu-Ni, zinc, epoxy, and gold, allowing you to customize the magnet for different environmental conditions.

With its high magnetic force, durable coating, and customizable features, this magnet is a perfect choice for use in motors, generators, and industrial audio equipment.

Product Attributes Table

| Parameter | Value |

| Tolerance | ±1% |

| Grade | N35 to N52, Customized |

| Material | NdFeB (Neodymium Magnet) |

| Shape | Customized (Disc, Block, Ring, etc.) |

| Coating | Ni-Cu-Ni, Zn, Epoxy, Ni-Au, etc. |

| Magnetization Direction | Axial, Diameter, Customized |

| Magnetic Force | Customized |

| Application | Industrial, Generator, Motor, Audio Equipment |

| Place of Origin | Jiangxi, China |

| Delivery Time | 22-30 days |

| Certification | ISO9001:2008, RoHS, ISO/TS16949:2009 |

| Founded | Since 2012 |

Features of Diametrically Magnetised NdFeB Ring Magnet

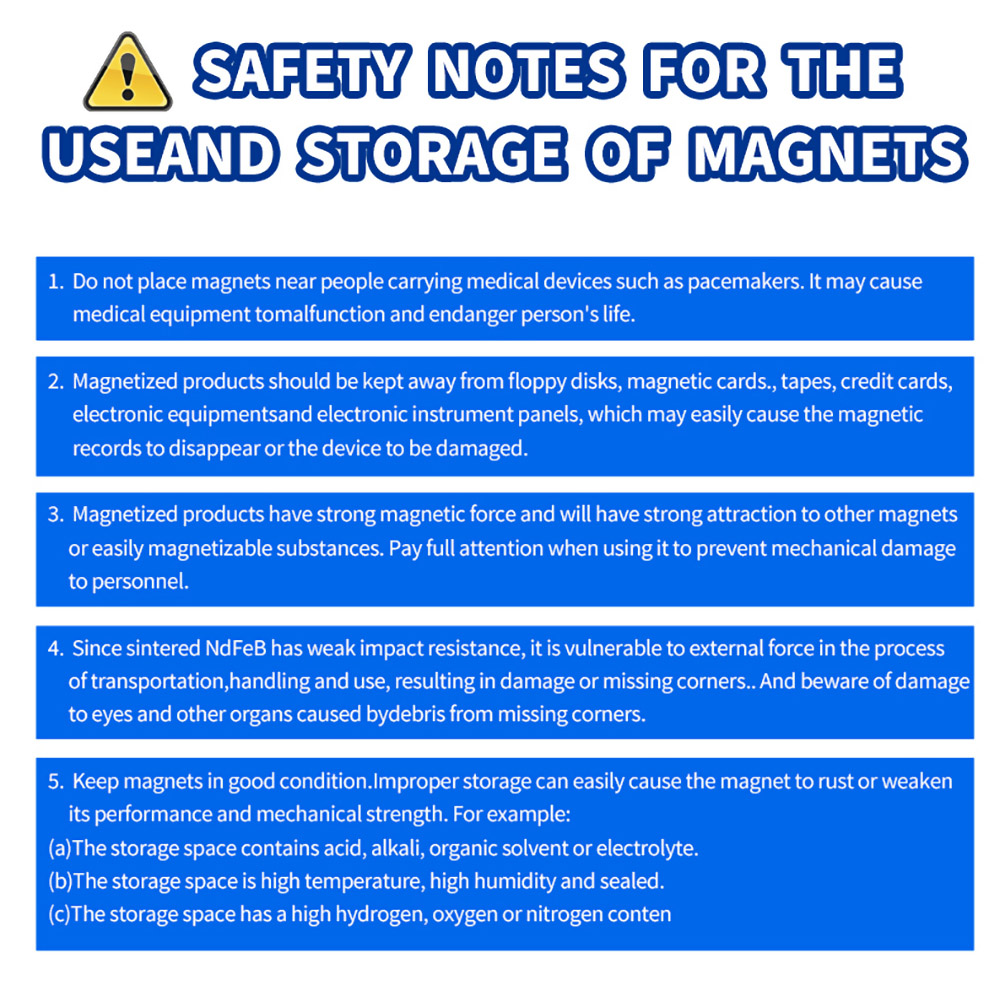

Material: Made of high strength N52 grade NdFeB (neodymium iron boron) for durability and superior performance.

Custom Sizes: Custom sizes available to meet specific customer requirements.

Coating Options: Choose from a variety of coatings including zinc, nickel, gold, nickel copper nickel and epoxy for protection and durability.

Quality Control: SST tested for 24-72 hours with a pass rate of up to 98%.

Advantages of Diametrically Magnetised NdFeB Ring Magnet

Wide Range of Grades: Available in grades from N35 to N54, including high temperature grades such as N35H and N50UH for demanding applications.

Customizable Shapes: Available in a variety of shapes such as cylindrical, disc, ring, block, countersunk, and irregular shapes to meet specific requirements.

Flexible Sizes: Available in custom sizes, allowing you to select a magnet that fits your equipment and application needs.

Various Coatings: Available in a variety of coating options including zinc, nickel-copper-nickel, gold, and epoxy for enhanced corrosion resistance.

Precision Manufacturing: Manufactured to tight tolerances to provide reliable performance in industrial and audio applications.

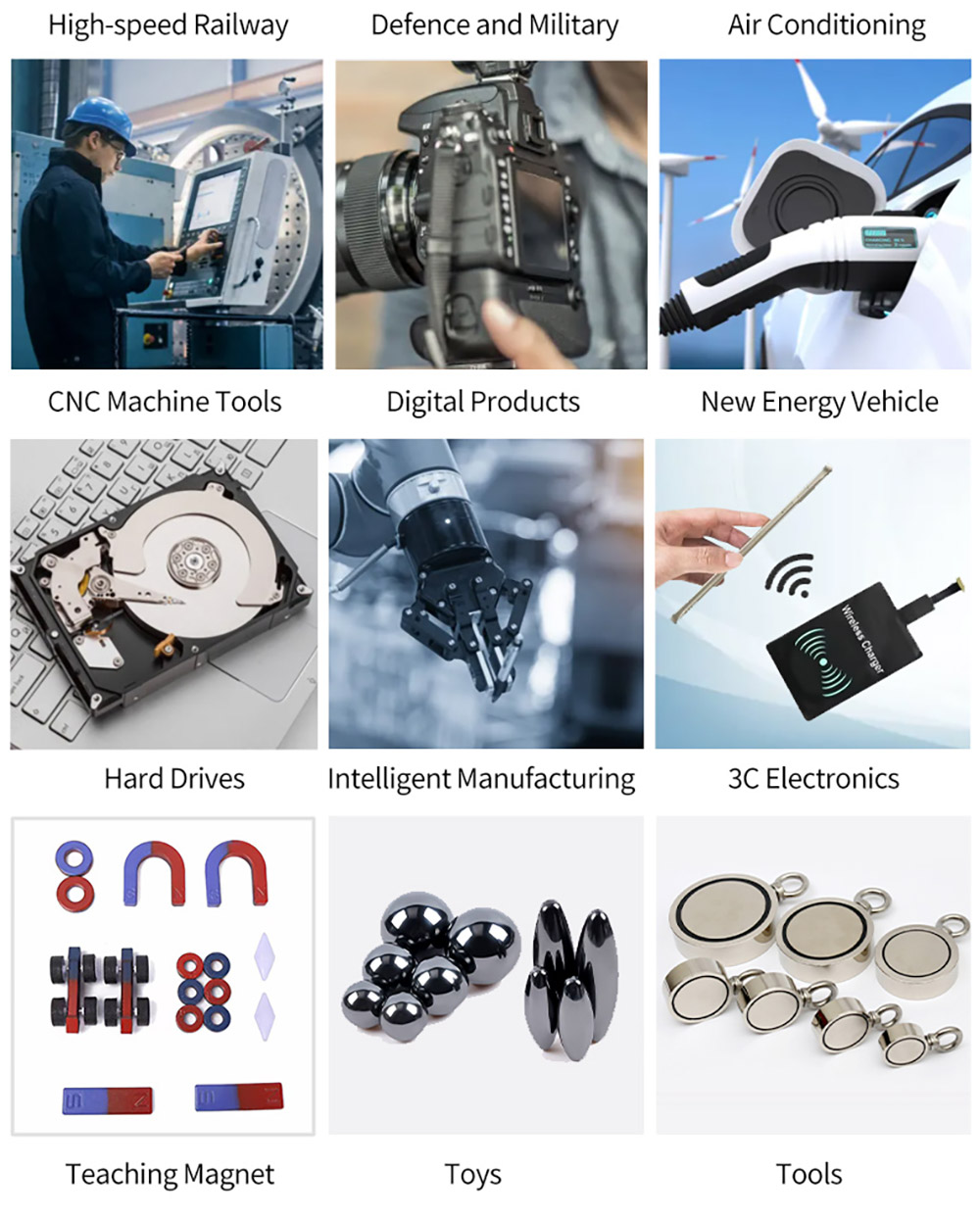

Versatile Applications: Ideal for audio equipment, motors, generators, and other industrial uses requiring high magnetic performance.

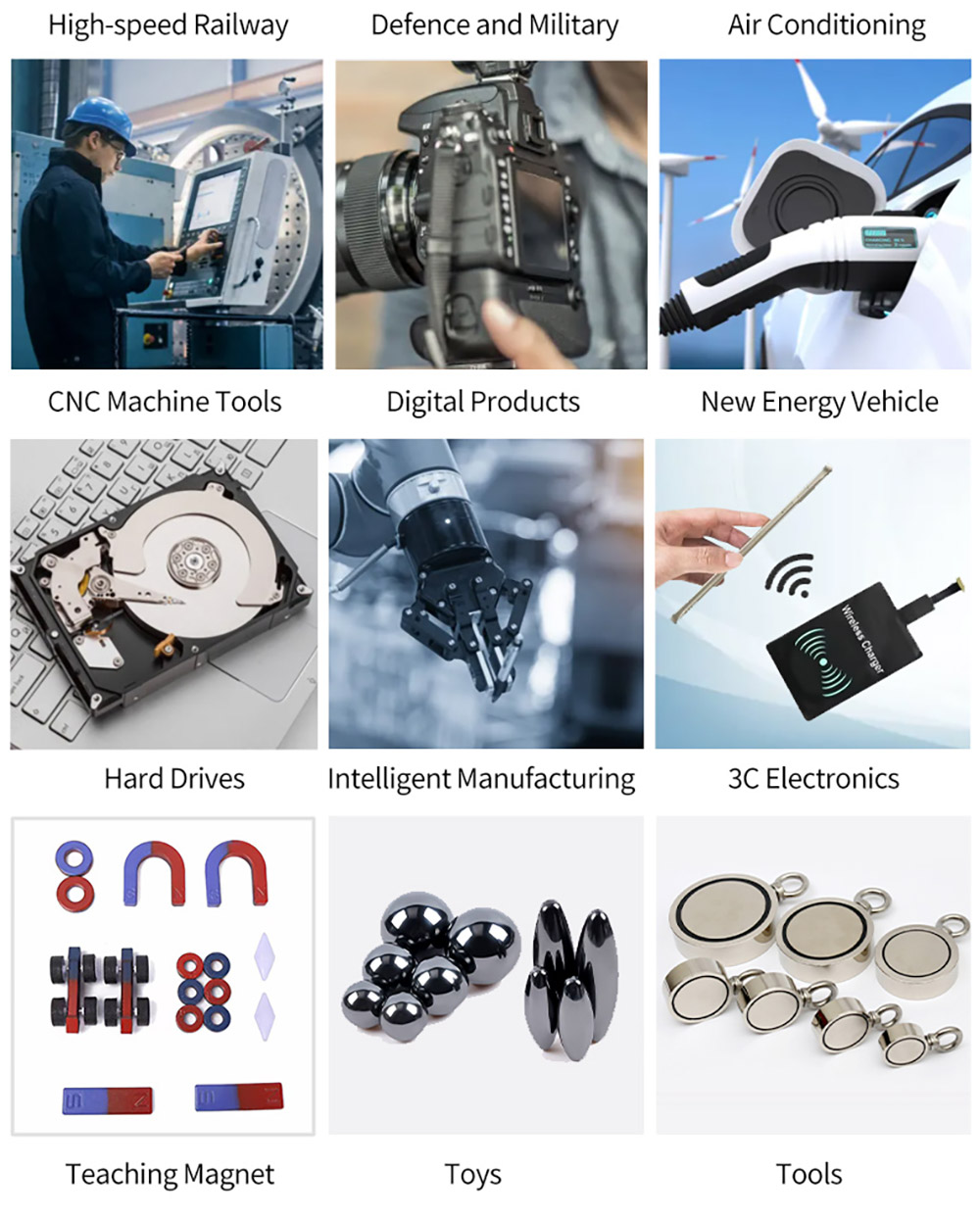

Applications of Diametrically Magnetised NdFeB Ring Magnet

Speaker Systems: Used in high-quality speakers for magnetic coupling and sound enhancement.

Hard Drives: Ideal for use in data storage devices that require stable and strong magnets.

Audio Devices: Commonly used in microphones, pickups, headphones, and speakers for clear and efficient sound transmission.

Dentures: Used in dental applications to ensure a secure connection and ease of use.

Magnetic Coupled Pumps: Essential in pumps for contactless energy transfer to prevent leakage.

Door Locks: Used in door mechanisms for secure closure without mechanical parts.

Motors and Generators: Used in motors and generators for efficient power conversion.

Jewelry: Used in magnetic jewelry for innovative designs and functionality.

Bearings: Used in bearings for precise motion control in a variety of mechanical applications.

FAQs of Diametrically Magnetised NdFeB Ring Magnet

1. What is a Diameter Magnetized NdFeB Ring Magnet?

A Diameter Magnetized NdFeB Ring Magnet is a magnet with a magnetic field that runs through its diameter. It is often used in applications that require strong, concentrated magnetic force, such as audio equipment.

2. What are the applications of Diameter Magnetized NdFeB Ring Magnets?

These magnets are often used in speaker systems, microphones, headphones, hard drives, and other audio equipment. They are also used in motors, generators, and magnetically coupled pumps.

3. What are the strengths and grades of these magnets?

Yueci offers a range of grades from N35 to N52 for optimal strength, including options for different temperatures (e.g. N35M to N54H).

4. How durable are Diameter Magnetized NdFeB Ring Magnets?

These magnets are made of high-strength N52 NdFeB (Neodymium Iron Boron), ensuring excellent durability and performance in demanding applications.

5. Do these magnets have a quality control process?

Yes, we conduct thorough quality control, including 24-72 hours of SST (Salt Spray Test), ensuring a high pass rate of 98%.

| Grade | Br | Hc | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m³ |

| min | max | min | max | min | min | min | min | min | max | min | max |

| N25 | 980 | 1020 | 9.8 | 10.2 | 8 | 637 |

|

| 22 | 27 | 175 | 215 |

| N28 | 1030 | 1070 | 10.3 | 10.7 | 8.5 | 677 |

|

| 25 | 30 | 199 | 239 |

| N30 | 1060 | 1100 | 10.6 | 11 | 9.5 | 756 |

|

| 27 | 32 | 215 | 255 |

| N33 | 1120 | 1140 | 11.2 | 11.4 | 10.5 | 836 |

|

| 30 | 35 | 239 | 279 |

| N34 | 1140 | 1170 | 11.4 | 11.7 | 11 | 876 |

|

| 31 | 36 | 247 | 287 |

| N35 | 1180 | 1220 | 11.8 | 12.2 | 12 | 955 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| N38 | 1230 | 1250 | 12.3 | 12.5 | 12 | 955 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| N40 | 1260 | 1280 | 12.6 | 12.8 | 12 | 955 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| N42 | 1290 | 1320 | 12.9 | 13.2 | 12 | 955 | 11.6 | 923 | 40 | 44 | 318 | 350 |

| N45 | 1330 | 1380 | 13.3 | 13.8 | 12 | 955 | 11.0 | 876 | 43 | 47 | 342 | 374 |

| N48 | 1370 | 1420 | 13.7 | 14.2 | 12 | 955 | 11.2 | 892 | 45 | 50 | 358 | 398 |

| N50 | 1390 | 1440 | 13.9 | 14.4 | 12 | 955 | 11.0 | 876 | 47 | 52 | 374 | 414 |

| N52 | 1420 | 1470 | 14.2 | 14.7 | 12 | 955 | 11.0 | 876 | 49 | 54 | 390 | 4.30 |

| N54 | 1450 | 1490 | 14.5 | 14.9 | 11 | 876 | 9.0 | 716 | 51 | 56 | 406 | 446 |

| N55 | 1460 | 1520 | 14.6 | 15.2 | 11 | 876 | 9.0 | 716 | 52 | 57 | 414 | 454 |

| N56 | 1470 | 1530 | 14.7 | 15.3 | 11 | 876 | 9.0 | 716 | 53 | 58 | 422 | 462 |

| N58 | 1490 | 1550 | 14.9 | 15.5 | 11 | 876 | 9.0 | 716 | 55 | 60 | 438 | 478 |

| 35M | 1180 | 1220 | 11.8 | 12.2 | 14 | 1114 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38M | 1230 | 1250 | 12.3 | 12.5 | 14 | 1114 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| 40M | 1260 | 1280 | 12.6 | 12.8 | 14 | 1114 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42M | 1290 | 1320 | 12.9 | 13.2 | 14 | 1114 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45M | 1330 | 1380 | 13.3 | 13.8 | 14 | 1114 | 12.5 | 995 | 43 | 47 | 342 | 374 |

| 48M | 1370 | 1420 | 13.7 | 14.2 | 14 | 1114 | 12.8 | 1019 | 45 | 50 | 358 | 398 |

| 50M | 1390 | 1440 | 13.9 | 14.4 | 14 | 1114 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52M | 1420 | 1470 | 14.2 | 14.7 | 13 | 1035 | 12.5 | 995 | 49 | 54 | 390 | 430 |

| 55M | 1460 | 1520 | 14.6 | 15.2 | 13 | 1035 | 12.8 | 1019 | 52 | 57 | 414 | 454 |

| 30H | 1080 | 1140 | 10.8 | 11.4 | 17 | 1353 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33H | 1140 | 1180 | 11.4 | 11.8 | 17 | 1353 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35H | 1180 | 1220 | 11.8 | 12.2 | 17 | 1353 | 10.9 | 868 | 33 | 37 | 263 | 295 |

| 38H | 1230 | 1250 | 12.3 | 12.5 | 17 | 1353 | 11.3 | 899 | 36 | 40 | 287 | 318 |

| Grade | Br | Hci | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| min | max | min | max | min | min | min | min | min | max | min | max |

| 40H | 1260 | 1280 | 12.6 | 12.8 | 17 | 1353 | 11.6 | 923 | 38 | 42 | 302 | 334 |

| 42H | 1290 | 1320 | 12.9 | 13.2 | 17 | 1353 | 12.0 | 955 | 40 | 44 | 318 | 350 |

| 45H | 1330 | 1380 | 13.3 | 13.8 | 17 | 1353 | 12.2 | 971 | 43 | 47 | 342 | 374 |

| 48H | 1370 | 1420 | 13.7 | 14.2 | 17 | 1353 | 12.9 | 1027 | 45 | 50 | 358 | 398 |

| 50H | 1390 | 1440 | 13.9 | 14.4 | 17 | 1353 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52H | 1420 | 1470 | 14.2 | 14.7 | 17 | 1353 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54H | 1440 | 1500 | 14.4 | 15 | 16 | 1274 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 55H | 1460 | 1520 | 14.6 | 15.2 | 16 | 1274 | 13.5 | 1075 | 52 | 57 | 414 | 454 |

| 30SH | 1080 | 1140 | 10.8 | 11.4 | 20 | 1592 | 10.3 | 820 | 27 | 32 | 215 | 255 |

| 33SH | 1140 | 1170 | 11.4 | 11.7 | 20 | 1592 | 10.6 | 844 | 31 | 35 | 247 | 279 |

| 35SH | 1180 | 1220 | 11.8 | 12.2 | 20 | 1592 | 11.0 | 876 | 33 | 37 | 263 | 295 |

| 38SH | 1230 | 1250 | 12.3 | 12.5 | 20 | 1592 | 11.4 | 907 | 36 | 40 | 287 | 318 |

| 40SH | 1260 | 1280 | 12.6 | 12.8 | 20 | 1592 | 11.8 | 939 | 38 | 42 | 302 | 334 |

| 42SH | 1290 | 1320 | 12.9 | 13.2 | 20 | 1592 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45SH | 1330 | 1380 | 13.3 | 13.8 | 20 | 1592 | 12.3 | 979 | 43 | 47 | 342 | 374 |

| 48SH | 1370 | 1420 | 13.7 | 14.2 | 20 | 1592 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50SH | 1390 | 1440 | 13.9 | 14.4 | 19 | 1512 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52SH | 1420 | 1470 | 14.2 | 14.7 | 19 | 1512 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 54SH | 1450 | 1500 | 14.5 | 15 | 19 | 1512 | 13.5 | 1075 | 51 | 56 | 406 | 446 |

| 30UH | 1080 | 1130 | 10.8 | 11.3 | 25 | 1990 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33UH | 1140 | 1170 | 11.4 | 11.7 | 25 | 1990 | 10.7 | 852 | 31 | 35 | 247 | 279 |

| 35UH | 1180 | 1220 | 11.8 | 12.2 | 25 | 1990 | 10.8 | 860 | 33 | 37 | 263 | 295 |

| 38UH | 1230 | 1250 | 12.3 | 12.5 | 25 | 1990 | 11.0 | 876 | 36 | 40 | 287 | 318 |

| 40UH | 1260 | 1280 | 12.6 | 12.8 | 25 | 1990 | 11.5 | 915 | 38 | 42 | 302 | 334 |

| 42UH | 1290 | 1330 | 12.9 | 13.3 | 25 | 1990 | 12.2 | 971 | 40 | 44 | 318 | 350 |

| 45UH | 1330 | 1380 | 13.3 | 13.8 | 25 | 1990 | 12.6 | 1003 | 43 | 47 | 342 | 374 |

| 48UH | 1370 | 1420 | 13.7 | 14.2 | 24 | 1910 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50UH | 1390 | 1440 | 13.9 | 14.4 | 24 | 1910 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| 52UH | 1420 | 1470 | 14.2 | 14.7 | 24 | 1910 | 13.2 | 1051 | 49 | 54 | 390 | 430 |

| 30EH | 1080 | 1130 | 10.8 | 11.3 | 30 | 2388 | 10.2 | 812 | 28 | 32 | 223 | 255 |

| 33EH | 1140 | 1170 | 11.4 | 11.7 | 30 | 2388 | 10.3 | 820 | 31 | 35 | 247 | 279 |

| 35EH | 1180 | 1220 | 11.8 | 12.2 | 30 | 2388 | 10.5 | 836 | 33 | 37 | 263 | 295 |

| 38EH | 1220 | 1250 | 12.2 | 12.5 | 30 | 2388 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40EH | 1250 | 1280 | 12.5 | 12.8 | 30 | 2388 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42EH | 1280 | 1320 | 12.8 | 13.2 | 29 | 2308 | 12.2 | 971 | 39 | 44 | 310 | 350 |

| 45EH | 1320 | 1380 | 13.2 | 13.8 | 29 | 2308 | 12.6 | 1003 | 42 | 47 | 334 | 374 |

| 48EH | 1370 | 1420 | 13.7 | 14.2 | 29 | 2308 | 12.5 | 995 | 45 | 50 | 358 | 398 |

| 50EH | 1390 | 1440 | 13.9 | 14.4 | 29 | 2308 | 13.0 | 1035 | 47 | 52 | 374 | 414 |

| Grade | Br | Hcj | Hcb | BH(max) |

| mT | kGs | kOe | kA/m | kOe | kA/m | MGOe | kJ/m^3 |

| mim | max | mm | TR | min | min | min | mim | mml | m2x | min | max |

| 28AH | 1020 | 1090 | 10.2 | 10.9 | 34 | 2760 | 9.8 | 780 | 25 | 30 | 199 | 239 |

| 30AH | 1070 | 1130 | 10.7 | 11.3 | 34 | 2760 | 10.2 | 812 | 27 | 32 | 215 | 255 |

| 33AH | 1110 | 1170 | 11.1 | 11.7 | 34 | 2706 | 10.5 | 836 | 30 | 35 | 239 | 279 |

| 35AH | 1170 | 1220 | 11.7 | 12.2 | 34 | 2706 | 10.5 | 836 | 32 | 37 | 255 | 295 |

| 38AH | 1220 | 1250 | 12.2 | 12.5 | 34 | 2706 | 11.5 | 915 | 35 | 40 | 279 | 318 |

| 40AH | 1250 | 1280 | 12.5 | 12.8 | 34 | 2706 | 11.9 | 947 | 37 | 42 | 295 | 334 |

| 42AH | 1280 | 1320 | 12.8 | 13.2 | 34 | 2706 | 12.2 | 971 | 39 | 44 | 310 | 350 |